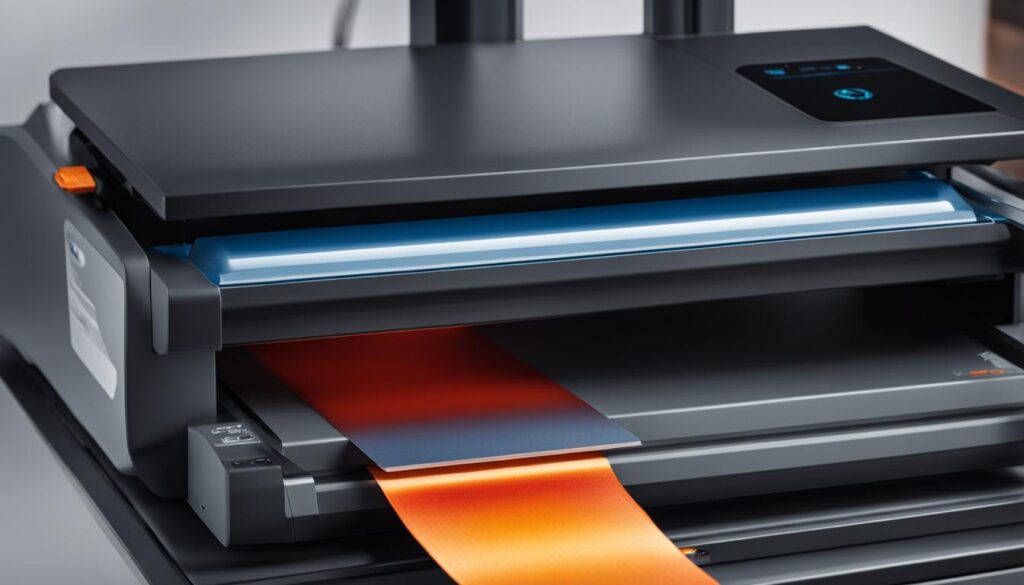

Heat presses are versatile crafting tools that can sometimes experience common problems. In this article, I will explore troubleshooting tips for heat press temperature display issues in Celsius. We will cover issues such as the heat press not heating up, not turning on, shutting off, tripping the breaker, temperature fluctuations, and other common problems that may arise when using a heat press.

Key Takeaways:

- Heat presses can encounter temperature display issues in Celsius.

- Common problems include heat press not heating up, not turning on, shutting off, tripping the breaker, and temperature fluctuations.

- Troubleshooting steps can involve checking and replacing heat sensors, inspecting and replacing relay switches, tightening platen connections, and ensuring sufficient power supply.

- Other common problems when using a heat press include irregular print application, scorching of fabrics, incorrect design placement, and fading or discoloration of prints.

- Resetting the heat press and inspecting for blown fuses are additional troubleshooting steps.

Troubleshooting Tip 1: Heat Press Not Heating Up

One common issue with heat presses is when the device powers up but does not heat up properly. This can be caused by a poorly functioning heat sensor, problems with the relay switch, weak platen connections, or insufficient power.

To fix this issue, you can try the following troubleshooting steps:

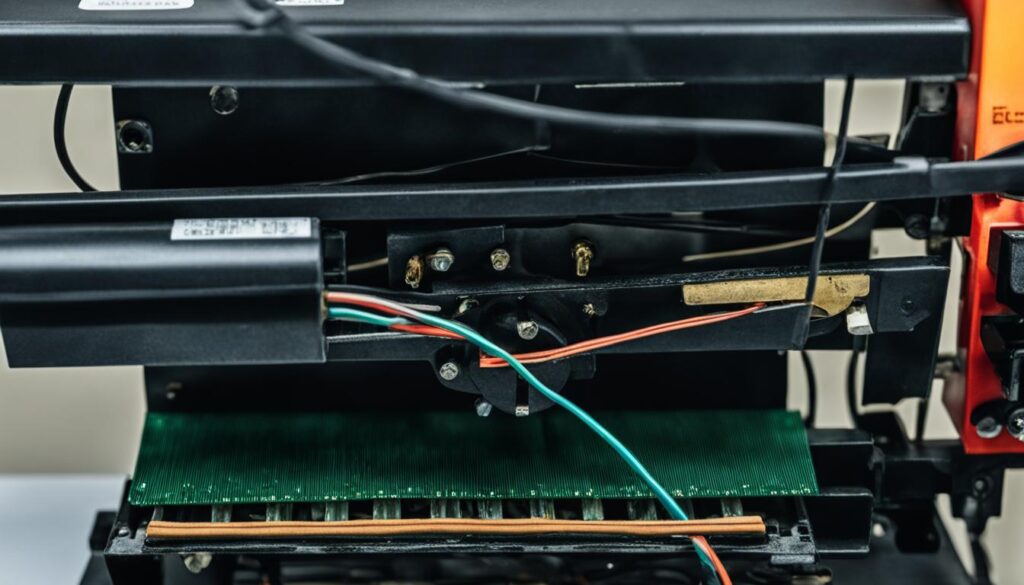

- Check and replace the heat sensor: A malfunctioning heat sensor can prevent the heat press from reaching the desired temperature. Inspect the sensor for any damage or disconnection, and replace it if necessary.

- Inspect and replace the relay switch: The relay switch controls the flow of electricity to the heating elements. If it is faulty, the heat press may not heat up properly. Check the relay switch for any signs of damage or malfunction and replace it if needed.

- Tighten the platen connections: Weak connections between the platen and the heating elements can result in insufficient heat transfer. Ensure that the connections are secure and tighten them if necessary.

- Ensure sufficient power supply: Inadequate power supply can affect the performance of the heat press. Make sure that the heat press is connected to a reliable power source and that there are no power fluctuations or interruptions.

If you have gone through these troubleshooting steps and the heat press still does not heat up properly, it is recommended to contact the manufacturer or supplier for further assistance and professional repair.

I had been facing the issue of my heat press not heating up properly. After checking the heat sensor, relay switch, and tightening the platen connections, I finally discovered that the problem was due to insufficient power supply. Once I ensured a stable power source, my heat press started working perfectly.

Troubleshooting Tip 2: Heat Press Won’t Turn On

Another common issue that heat press users may encounter is when their heat press won’t turn on. This problem can be frustrating, especially when you’re in the midst of a pressing project. However, there are a few possible causes for this issue that you can troubleshoot.

First, check the power cable and wires for any visible damage. Over time, cables can become worn or frayed, leading to connectivity issues. If you notice any damage, it may be necessary to replace the power cable. Ensure that the new cable is securely connected to both the heat press and the power source.

If the power cable appears to be intact, the next step is to inspect the fuse. A blown fuse can prevent the heat press from turning on. To check the fuse, locate the fuse compartment on your heat press. Open it and visually examine the fuse. A blown fuse will have a break in the metal filament. If you find a blown fuse, replace it with a new one of the same rating.

If you have checked the power cable and fuse but the heat press still won’t turn on, it is recommended to contact the supplier or manufacturer for further assistance. They will be able to guide you through additional troubleshooting steps or provide instructions for repair or replacement if necessary.

Remember: Always ensure that the heat press is properly connected to a reliable power source. Avoid using extension cords or power outlets with other high-power-consuming devices simultaneously to prevent overloading the circuit and potentially damaging your heat press.

| Possible Causes | Troubleshooting Steps |

|---|---|

| Damage to power cable | Inspect for damage and replace if necessary. |

| Blown fuse | Check the fuse compartment, replace with a new fuse of the same rating if blown. |

| Other electrical issues | Contact the supplier or manufacturer for further assistance. |

Troubleshooting Tip 3: Heat Press Keeps Shutting Off

If your heat press heats up fine but then suddenly shuts off, it can be frustrating and disruptive to your workflow. Several issues can cause this problem, including a faulty breaker, compromised wires, or outlet overload. To resolve this issue, follow the troubleshooting steps below:

Inspect the Breaker

Start by checking the breaker for any signs of damage or tripping. A faulty breaker can cause the heat press to shut off unexpectedly. If you notice any issues with the breaker, it may need to be repaired or replaced. Consult a professional if you are unsure how to proceed.

Reduce Outlet Load

Another possible cause of the heat press shutting off is an overloaded outlet. If there are too many devices connected to the same outlet, it can exceed its capacity and trigger a circuit breaker. Try unplugging other devices from the outlet or redistribute the load to a different outlet. This can help alleviate the strain on the circuit and prevent further interruptions.

Note: It’s important to use a dedicated outlet for your heat press to ensure it receives adequate power without overloading the circuit.

If the issue persists after inspecting the breaker and reducing the outlet load, it’s recommended to contact a professional technician or the manufacturer for further assistance. They will be able to diagnose the problem accurately and provide appropriate solutions.

By addressing the issue of your heat press unexpectedly shutting off, you can minimize disruptions during your crafting projects and ensure a smoother workflow.

Troubleshooting Tip 4: Heat Press Keeps Tripping Breaker

If your heat press consistently trips the breaker, it can be frustrating and disrupt your workflow. This issue is often caused by compromised heating elements or wires within the heat press. When these components are compromised, excessive currents flow through the circuit, triggering the breaker as a safety measure.

To resolve the problem of your heat press tripping the breaker, it is important to address the underlying issue. I recommend contacting a professional technician who specializes in heat press repairs. They will have the expertise to inspect and identify the specific components that are causing the breaker to trip.

Once the faulty components have been identified, the professional technician can replace them to restore the proper functioning of your heat press. It is crucial to have these repairs done by a qualified individual to ensure the safety and performance of your heat press.

Remember, attempting to fix the issue yourself without proper knowledge and experience may result in further damage to the heat press or personal injury. So it’s always best to leave it to the experts!

Common Causes of Heat Press Breaker Tripping:

- Compromised heating elements

- Faulty wires

- Excessive currents

“A professional technician can inspect and replace the faulty components, restoring your heat press’s functionality and preventing further breaker trips.”

Troubleshooting Tip 5: Heat Press Temperature Fluctuating

If your heat press temperature keeps fluctuating below the set point, it can be frustrating and affect the quality of your heat transfers. This issue may indicate that the temperature system of your heat press is damaged or not receiving a sufficient power supply. Resolving this problem is crucial to ensure consistent and accurate temperature control during your crafting projects.

To address the heat press temperature fluctuation issue, there are a few steps you can take:

- Contact the Supplier or Manufacturer: If you notice temperature fluctuations in your heat press, it is best to reach out to the supplier or manufacturer. Explain the problem you are experiencing, and provide as much detail as possible about the fluctuations. They will be able to guide you through the next troubleshooting steps specific to your heat press model.

- Component Replacement: In some cases, the temperature system of the heat press may require component replacement. The supplier or manufacturer will be able to identify the affected components and provide you with instructions on how to replace them. It is essential to follow their guidance to ensure proper installation and functionality.

- Power Supply Check: Fluctuating temperature can also be a result of insufficient power supply to the heat press. Make sure that the heat press is connected to a dedicated outlet and not sharing power with other high-power-consuming devices. Additionally, inspect the power cord and plug for any damage and ensure a secure connection.

“Fluctuating temperatures can significantly impact the quality of heat transfer projects. Addressing this issue promptly will help you achieve consistent results and avoid potential crafting mishaps.”

By following these troubleshooting steps and consulting the supplier or manufacturer, you can resolve heat press temperature fluctuation issues effectively. This will ensure that your heat press operates optimally, providing you with reliable and precise temperature control for your crafting needs.

Troubleshooting Tip 6: Other Common Problems When Using Heat Press

In addition to the aforementioned issues, there are other common problems that may occur when using a heat press. These include:

- Irregular print application

- Scorching of fabrics

- Incorrect design placement

- Fading or discoloration of prints

These problems can be frustrating but rest assured, there are solutions. To address irregular print application, it’s important to check the temperature, time, and pressure requirements for different materials. Using high-quality ceramics and fabrics can prevent scorching and ensure better results. Proper design placement guidelines should be followed to avoid any mishaps. Lastly, if you notice fading or discoloration of prints, adjusting the temperature and pressure settings might help.

Remember, troubleshooting these common heat press problems requires attention to detail and patience. By taking the necessary steps and following these guidelines, you can overcome these challenges and achieve the desired results.

Expert Tip:

“When troubleshooting heat press problems, it’s essential to identify the underlying cause. By understanding the root issue, you can take targeted steps to resolve it, saving time and minimizing frustration.” – [Expert Name], Heat Press Specialist

How to Reset a Heat Press

If you’re experiencing any issues with your heat press, performing a reset can often resolve the problem. There are two methods you can use to reset your heat press:

- Using the Reset Button: Many heat press machines come with a reset button specifically designed for this purpose. Locate the reset button on your machine and press it to initiate the reset process.

- Unplugging and Plugging Back In: Another simple way to reset your heat press is by unplugging the machine from the power source, waiting for a few seconds, and then plugging it back in. This can help clear any temporary glitches that may be affecting the functionality of your heat press.

By performing a reset, you can restore the normal operation of your heat press and address any issues it may be experiencing.

Remember, it’s essential to consult the manufacturer’s instructions or contact their customer support if you encounter any difficulties during the reset process or if the issues persist after resetting the heat press.

How to Know If Your Heat Press Fuse Is Blown

To determine if your heat press fuse is blown, you can visually inspect the fuse by opening the fuse compartment. A blown fuse typically has a break in the metal filament. If you suspect a blown fuse, it is recommended to replace it to ensure proper functioning of the heat press.

Inspecting the Fuse

Inspecting the fuse is an important step in troubleshooting heat press issues. Follow these steps:

- Turn off and unplug your heat press to ensure safety.

- Locate the fuse compartment on your heat press. This is usually located near the power input.

- Remove the fuse cover by gently prying it open or unscrewing it, depending on the design of your heat press.

- Take a close look at the fuse. A blown fuse will have a visible break in the metal filament, indicating that it needs to be replaced.

It’s important to note that heat press fuses are typically small and can be easily replaced. Consult your heat press manufacturer or supplier for the correct type of fuse to use as a replacement.

Replacing the Fuse

When replacing the blown fuse, follow these steps:

- Make sure your heat press is turned off and unplugged.

- Identify the correct replacement fuse. This information can usually be found in your heat press’s user manual or by contacting the manufacturer or supplier.

- Line up the replacement fuse with the fuse slots in the compartment.

- Insert the replacement fuse into the slots and ensure it is seated securely.

- Replace the fuse cover by closing or screwing it back into place.

Once the fuse is replaced, you can plug in your heat press and test its functionality. If the heat press still does not work or experiences other issues, it is advisable to consult a professional technician or contact the manufacturer for further assistance.

By regularly inspecting and replacing blown fuses in your heat press, you can ensure that it operates safely and reliably, allowing you to continue crafting without interruptions.

Adjusting Tension Knob and Sensor for Heat Press

If your heat press won’t stay down or won’t count down, it may be necessary to adjust the tension knob and sensor. The tension knob and sensor play crucial roles in ensuring the proper operation of your heat press.

To begin, locate the tension knob on your heat press machine. The tension knob is responsible for controlling the pressure applied to your materials during heat transfer. If the tension is too loose, your heat press may not apply sufficient pressure, resulting in incomplete or uneven transfers. Conversely, if the tension is too tight, it can strain the machine and compromise the quality of your prints.

To adjust the tension knob:

- Turn the tension knob counterclockwise to loosen the pressure.

- Place your materials on the heat platen and position them as desired.

- Gently lower the upper heat platen onto the materials.

- Rotate the tension knob clockwise to gradually increase the pressure until it reaches the desired level.

Ensure that the tension knob is set appropriately for the type of material you are working with. Different materials may require different levels of pressure for optimal results. Always refer to the manufacturer’s recommendations for your specific heat press model and the materials being used.

In addition to adjusting the tension knob, it is crucial to check and ensure that the heat press sensor is engaged properly. The heat press sensor is responsible for detecting and monitoring the temperature during the heat transfer process. If the sensor is not engaged correctly, it may affect the accuracy of temperature readings and subsequently impact the quality of your prints.

To ensure proper engagement of the heat press sensor:

- Inspect the sensor position and alignment.

- Make sure the sensor is securely in place and making contact with the heat platen.

- Adjust the position if needed to ensure proper contact and engagement.

By making adjustments to both the tension knob and sensor, you can resolve issues with your heat press not staying down or not counting down properly. These adjustments will help optimize the pressure and temperature control, allowing for consistent and accurate heat transfers.

| Issue | Possible Cause | Solution |

|---|---|---|

| Heat press won’t stay down | Tension knob too loose | Tighten the tension knob to increase pressure |

| Heat press won’t count down | Improper engagement of heat press sensor | Ensure proper alignment and contact of the sensor with the heat platen |

Conclusion

Troubleshooting heat press temperature display issues in Celsius is crucial for maintaining optimal performance of your heat press machine. By implementing the troubleshooting tips provided in this article, you can effectively address common problems that may arise during heat press operation. Whether you’re facing issues with heating, power supply, breaker tripping, or temperature fluctuations, these troubleshooting tips can help you diagnose and resolve the problem.

Remember, it is always advisable to consult your heat press machine’s supplier or manufacturer for further assistance and guidance. They can provide valuable insights specific to your machine’s make and model, ensuring that you receive accurate troubleshooting advice tailored to your equipment.

With proper troubleshooting techniques and support from professionals, you can overcome heat press temperature display issues and continue enjoying seamless crafting experiences. Maintain the functionality of your heat press machine by following the troubleshooting tips outlined in this article, and rest assured that you’ll be able to create beautiful and customized designs with ease.

FAQ

What should I do if my heat press is not heating up?

If your heat press is not heating up, it may be due to a faulty heat sensor, relay switch, weak platen connections, or insufficient power. You can troubleshoot this issue by checking and replacing the heat sensor, inspecting and replacing the relay switch, tightening the platen connections, or ensuring that your heat press is receiving sufficient power.

How can I fix my heat press if it won’t turn on?

If your heat press won’t turn on, it could be due to a damaged power cable or a blown fuse. To resolve this issue, you can check the power cable and wires for damage, replace the power cable if necessary, and inspect the fuse for any signs of a blown fuse. If the problem persists, it is advisable to contact the supplier or manufacturer for further assistance.

What should I do if my heat press keeps shutting off?

If your heat press consistently shuts off, it may be due to a faulty breaker, compromised wires, or an overloaded outlet. To troubleshoot this issue, you can inspect the breaker for damage, reduce the load on the outlet by unplugging other devices, and contact a professional if necessary.

Why does my heat press keep tripping the breaker?

If your heat press keeps tripping the breaker, it may be caused by compromised heating elements or wires, leading to excessive currents that trigger the circuit breaker. It is recommended to contact a professional for inspection and replacement of the defective parts.

How can I resolve temperature fluctuations in my heat press?

Temperature fluctuations in a heat press can be a result of a damaged temperature system or inadequate power supply. To address this issue, contact the supplier or manufacturer for component replacement and ensure proper power supply to the heat press.

What are some other common problems when using a heat press?

Other common problems when using a heat press include irregular print application, scorching of fabrics, incorrect design placement, and fading or discoloration of prints. Solutions for these problems include checking temperature, time, and pressure requirements for different materials, using high-quality ceramics and fabrics, and following proper design placement guidelines.

How do I reset my heat press?

To reset your heat press, you can use the device’s resetting button or unplug the machine and plug it back in. This can help restore functionality if the heat press is experiencing any issues.

How can I tell if my heat press fuse is blown?

To determine if your heat press fuse is blown, visually inspect the fuse by opening the fuse compartment. A blown fuse typically has a break in the metal filament. If you suspect a blown fuse, it is recommended to replace it to ensure the proper functioning of the heat press.

How do I adjust the tension knob and sensor for my heat press?

If your heat press won’t stay down or won’t count down, you may need to adjust the tension knob and sensor. Loosen the tension knob and ensure that the sensor is engaged properly. By making these adjustments, you can resolve issues with the heat press not staying down or not counting down properly.