Cleaning the upper platen of your heat press is crucial for maintaining its performance and extending its lifespan. A clean heat press platen ensures that your products are free from unwanted substances and transfers. In this guide, I will provide you with effective methods and best practices to clean your heat press platen and keep it in optimal condition.

Key Takeaways:

- Cleaning your heat press platen regularly is essential for optimal functioning.

- Follow the manufacturer’s recommendations for specific cleaning instructions.

- Consider using heat press platen cleaners like EZ Off for effective cleaning.

- If necessary, try chemicals like bleach or acetone for removing stubborn residues.

- “Cooking” off the unwanted substances using the heat press can be an efficient method.

Checking the Manufacturer’s Recommendations

Before attempting to clean your heat press platen, it’s important to refer to the manufacturer’s recommendations. Different heat press models may have specific cleaning instructions and recommended cleaning products. Following the manufacturer’s guidelines will help ensure that you clean the platen effectively without causing any damage to the machine. Consulting the user manual or contacting the manufacturer directly will provide you with the necessary information for proper maintenance and care.

Manufacturers understand the intricacies of their heat press designs and have tested various cleaning methods and products to ensure optimal performance. By adhering to their recommended cleaning practices, you can maintain the cleanliness and functionality of your heat press while prolonging its lifespan.

These recommendations can vary between manufacturers, taking into account factors such as platen material, coating, and type of residues commonly encountered during operation. Therefore, it’s crucial to familiarize yourself with the specific guidelines provided by your heat press manufacturer.

“Following the manufacturer’s recommendations guarantees that you clean and maintain your heat press according to industry standards. This ensures that your press functions optimally, delivering the best results for your projects.”

– Michelle Parker, Heat Press Expert

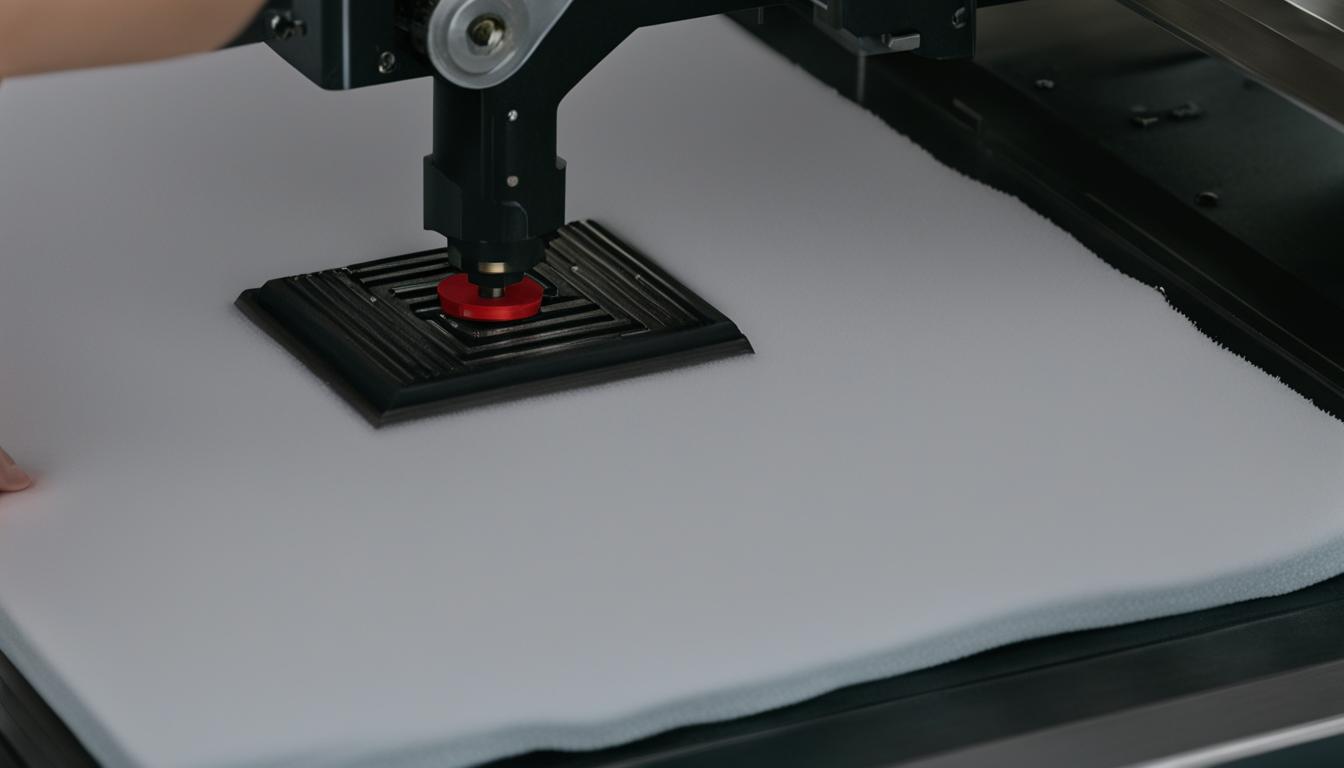

Using EZ Off Heat Press Platen Cleaner

If you’re looking for an effective solution to remove residue from your heat press platen, EZ Off Heat Press Platen Cleaner is a popular choice. This specially designed product is safe to use on various surfaces, including fabric, skin, and metal. Its powerful formula ensures a thorough clean, leaving your platen looking fresh and ready for use.

Here’s a step-by-step guide on how to use EZ Off Heat Press Platen Cleaner:

- Start by heating your heat press to around 200 degrees Fahrenheit. This will help soften the residue and make it easier to remove.

- Next, apply a small amount of the EZ Off cleaner onto a clean cotton rag. Be sure to use a rag that won’t scratch or damage the platen surface.

- Using small circular motions, gently rub the cleaner onto the platen. This will help loosen and remove the residue from the surface.

- As the rag becomes soiled, switch to a clean area to ensure effective cleaning.

- Continue the process until the platen is clean and free from any residue.

With its convenient and efficient cleaning properties, EZ Off Heat Press Platen Cleaner is a reliable solution for removing various types of residue. It’s a must-have tool for anyone looking to maintain the performance and longevity of their heat press platen.

Trying Chemicals for Cleaning

Vicki from Conde Systems suggests using chemicals like bleach, acetone, or rubbing alcohol to clean ink or other unwanted substances off the heat press platen. For best results, saturate a lint-free linen wipe with one of these cleaners and use small, firm strokes to remove the substance from the platen. Move to a different part of the wipe when one area gets dirty. Goo Gone is another recommended cleaner for removing sticky messes from the platen.

It’s important to note that when using chemicals, it’s advisable to wear protective gloves and ensure proper ventilation in the workspace. Different substances may require different chemicals for effective cleaning, so it’s recommended to test a small inconspicuous area before applying the cleaner to the entire platen.

“Cooking” off the Unwanted Substance

If the aforementioned cleaning methods don’t effectively remove the unwanted substances from the heat press platen, Vicky from Conde Systems suggests the method of “cooking” off the stain, film, ink, or other unwanted matter. This involves using the extreme heat of the press to slowly remove the substances over time.

However, it’s important to note that this method can be time-consuming and may require multiple applications. To begin the “cooking” process, turn on your heat press and set the temperature to the highest setting. Allow the heat press to reach the desired temperature, usually around 400 degrees Fahrenheit.

Once the heat press is heated, place a protective paper or cloth over the platen. This will prevent any accidental transfer of the unwanted material onto other products during the “cooking” process.

Next, carefully lay the stained or soiled area of the platen onto the protective paper. Apply gentle pressure to ensure the stained area is in direct contact with the paper. Allow the heat press to apply heat to the stained area for a few minutes.

After a few minutes, lift the heat press and check the progress. If the stain or residue has started to soften or loosen, you can gently scrub the area with a soft brush or cloth to aid in the removal process. Be cautious not to apply too much pressure or scrub too harshly, as this may damage the platen.

Repeat the process of applying heat, checking the progress, and gently scrubbing until the stain is completely removed. It may take several attempts and a bit of patience, but “cooking” off the unwanted substances can prove to be an effective method for restoring the cleanliness of your heat press platen.

Once the stain is removed, be sure to thoroughly clean the platen using one of the recommended cleaning methods from previous sections. This will help remove any remaining residue or debris that may have been loosened during the “cooking” process.

Remember to always monitor the process closely and ensure that the stain is completely removed before using the press for other applications. It’s better to take the extra time and care to thoroughly clean the heat press platen than risk transferring unwanted substances onto your garments or products.

Below is a table summarizing the steps involved in the “cooking” method for removing stains from the heat press platen:

| Step | Description |

|---|---|

| 1 | Set the heat press to the highest temperature setting |

| 2 | Place a protective paper or cloth over the platen |

| 3 | Lay the stained area of the platen onto the protective paper |

| 4 | Apply heat for a few minutes |

| 5 | Check the progress and gently scrub if necessary |

| 6 | Repeat steps 4 and 5 until the stain is removed |

| 7 | Thoroughly clean the platen using the recommended cleaning methods |

By following these steps, you can effectively “cook” off the unwanted substances from your heat press platen and restore its cleanliness and functionality.

Best Practices for Cleaning Your Heat Press

In addition to following specific cleaning methods, there are some general best practices you can follow to keep your heat press platen clean and in optimal condition:

- Act quickly: When you notice residue or unwanted substances on the platen, it’s important to act promptly to prevent them from further baking onto the surface.

- Turn off and cool down: Before cleaning, ensure that the heat press is turned off and allowed to cool. This not only ensures your safety but also prevents accidental burns.

- Gentle cleaning: Use a soft cloth, such as a t-shirt or microfiber cloth, along with non-abrasive cleansers, to gently wipe down the platen. Avoid using abrasive cleaning pads or solutions with grit that can damage the platen’s surface.

- Regular maintenance: Regularly check and clean your heat press platen to maintain its cleanliness and functionality. By incorporating regular maintenance into your workflow, you can prevent the buildup of unwanted substances.

Remember to store your heat press in a cool, dry area when not in use to prevent moisture and rust. Following these best practices will help ensure that your heat press remains in excellent working condition and continues to produce high-quality prints.

What to Clean Your Heat Press With

When it comes to cleaning your heat press, choosing the right materials is crucial for achieving optimal results. Different cleaning methods may be required based on the type of residue or substance you’re dealing with. Here are some effective heat press cleaning materials:

- Mild Soap and Warm Water: For regular cleaning, mild soap and warm water are often sufficient. They are gentle yet effective in removing dirt, debris, and ink smudges from the platen surface.

- Mineral Spirits: When more aggressive cleaning is needed, mineral spirits can be used. This solvent is excellent for dissolving oil-based materials and adhesive residue without causing damage to the platen surface.

- Non-Abrasive Hand Cleaner: Another option for effective cleaning is a non-abrasive hand cleaner. This type of cleaner is designed to remove grease, ink, and other stubborn substances without scratching or harming the platen.

When using these cleaning materials, it’s important to read the instructions and labels to ensure proper usage. Additionally, it’s advisable to follow safety precautions, such as working in a well-ventilated area and wearing protective gloves if necessary.

Cleaning Your Teflon Coated Heat Press

Teflon coated heat presses require special care to avoid damaging the coating. It’s important to be gentle and avoid scrubbing or scraping the surface with abrasive materials. Mild soap and warm water can be used for regular cleaning, but be cautious not to wear down the Teflon coating. If additional cleaning is needed, mineral spirits or similar solvents can be used, but again, be gentle.

To protect the Teflon coating and make future cleaning easier, it’s recommended to apply a Teflon spray on the upper platen periodically. This extra coating can help minimize the accumulation of residue and prevent the transfer of impurities onto garments.

How Often Should You Clean Your Heat Press?

The frequency of cleaning your heat press platen depends on various factors, including the usage and type of applications. As a general rule, it’s recommended to check and clean your heat press once a week for regular usage. This ensures that any residue or unwanted substances are promptly removed before they become baked onto the platen surface.

However, if you don’t use your heat press frequently, cleaning it once a month may be sufficient. It’s important to establish a regular cleaning schedule and incorporate it into your workflow to maintain the cleanliness and functionality of your heat press.

Regular cleaning not only helps in preserving the lifespan of your equipment, but it also ensures that your heat press consistently delivers high-quality prints. By keeping your heat press clean, you can avoid any unwanted transfer of substances onto your products, thereby maintaining their quality and customer satisfaction.

Factors Affecting Cleaning Frequency:

- The type of materials and substances you work with: Different materials and substances may leave varying degrees of residue on your platen, requiring more frequent cleaning.

- The intensity of usage: If you use your heat press on a daily basis or for extended periods, it’s advisable to clean it more frequently to prevent the buildup of residue and stains.

- The nature of your applications: Certain applications, such as working with sublimation inks or specialty transfers, may result in a higher likelihood of residue buildup, necessitating more frequent cleaning.

By considering these factors and being attentive to the condition of your heat press, you can determine an appropriate cleaning schedule that suits your specific needs. Remember, regular maintenance is key to keeping your heat press in optimal condition and ensuring consistent performance.

Conclusion

Cleaning and maintaining your heat press platen is crucial for ensuring its optimal performance and longevity. By following the manufacturer’s recommendations, using specialized heat press platen cleaners, and adopting best practices, you can effectively clean your heat press platen and prevent unwanted substances from transferring onto your products. Regular cleaning is key to maintaining the cleanliness and functionality of your heat press. It is important to prioritize safety, carefully read instructions on cleaning products, and be gentle when cleaning Teflon-coated heat presses.

With proper care and maintenance, your heat press will continue to produce high-quality prints and serve you well for years to come. Remember that prevention is better than cure – act quickly when you notice residue or unwanted substances on the platen to prevent them from further baking onto the surface. Store your heat press in a cool, dry area when not in use to prevent moisture and rust. Following these heat press cleaning tips and maintaining your heat press platen regularly will help you achieve consistent and professional results in your printing projects.

Keep in mind that different cleaning methods and materials may be required depending on the type of residues or substances you need to remove. Always refer to the manufacturer’s guidelines and test any new cleaning products or methods on a small, inconspicuous area before applying them to the entire platen. By taking these precautions and being proactive in your heat press platen maintenance, you can prolong the lifespan of your heat press and ensure continuous success in your printing endeavors.

FAQ

How should I clean the upper platen on my heat press?

Cleaning the upper platen of your heat press is essential for maintaining its performance and longevity. There are various methods you can use to effectively clean your heat press platen, including following the manufacturer’s recommendations, using specific heat press platen cleaners like EZ Off, using chemicals like bleach or acetone, or “cooking” off the unwanted substances using the extreme heat of the press.

Should I follow the manufacturer’s recommendations when cleaning the upper platen?

Yes, it’s advisable to check the manufacturer’s recommendations before attempting to clean your heat press platen. Different heat press models may have specific cleaning instructions and recommended cleaning products. Following the manufacturer’s guidelines will help ensure that you clean the platen effectively without causing any damage to the machine.

How do I use EZ Off Heat Press Platen Cleaner?

To use EZ Off Heat Press Platen Cleaner, heat the press to around 200 degrees Fahrenheit, apply a small amount of the cleaner onto a clean cotton rag, and use small circular motions to rub and remove the residue from the platen. Switch to a different area of the rag when it becomes soiled. Repeat the process until the platen is clean.

What chemicals can I use to clean ink or unwanted substances off the platen?

You can use chemicals like bleach, acetone, rubbing alcohol, or Goo Gone to clean ink or other unwanted substances off the heat press platen. It’s important to wear protective gloves and ensure proper ventilation when using chemicals. Different substances may require different chemicals for effective cleaning, so it’s recommended to test a small inconspicuous area before applying the cleaner to the entire platen.

How can I “cook” off unwanted substances from the platen?

If the other cleaning methods don’t work, you can try the method of “cooking” off the stain, film, ink, or other unwanted matter. This involves using the extreme heat of the press to slowly remove the substances over time. It’s important to monitor the process closely and ensure that the stain is completely removed before using the press for other applications.

What are the best practices for cleaning my heat press platen?

Act quickly when you notice residue or unwanted substances on the platen, turn off the heat press and allow it to cool before cleaning, use a soft cloth and non-abrasive cleansers to gently wipe down the platen, and avoid abrasive cleaning pads or solutions with grit that can damage the platen’s surface.

What can I clean my heat press with?

Mild soap and warm water are commonly recommended for regular cleaning. If more aggressive cleaning is needed, you can use mineral spirits or non-abrasive hand cleaners. It’s important to read the instructions and labels of the cleaning products and ensure proper ventilation and safety precautions are followed when using solvents.

How do I clean my Teflon coated heat press?

To clean a Teflon coated heat press, use mild soap and warm water for regular cleaning. Avoid scrubbing or scraping the surface with abrasive materials. If additional cleaning is needed, you can use mineral spirits or similar solvents, but be gentle. It’s also recommended to apply a Teflon spray periodically to protect the coating and prevent the accumulation of residue.

How often should I clean my heat press?

The frequency of cleaning your heat press platen depends on factors like usage and type of applications. As a general rule, it’s recommended to check and clean your heat press once a week for regular usage. However, if you don’t use your heat press frequently, cleaning it once a month may be sufficient. It’s important to establish a regular cleaning schedule and incorporate it into your workflow to maintain the cleanliness and functionality of your heat press.

What should I keep in mind when cleaning my heat press platen?

When cleaning your heat press, prioritize safety, read instructions on cleaning products, be gentle, and store your heat press in a cool, dry area when not in use to prevent moisture and rust.