Cleaning the top pallet of a heat press is crucial for maintaining its performance and longevity. Accumulated ink, adhesive, and lint can affect the quality of prints and cause damage to the equipment. In this guide, I will share effective tips and best practices for cleaning the top pallet of a heat press.

When it comes to heat press maintenance, the top pallet often gets overlooked. However, regular cleaning is essential to keep your heat press in optimal condition and ensure consistent print results.

Key Takeaways:

- Regularly cleaning the top pallet of a heat press is crucial for maintaining its functionality and longevity.

- Using pallet tape can act as a barrier and prevent ink, adhesive, and lint from sticking to the surface of the top pallet.

- An on-press wash technique can effectively remove ink and adhesive from the top pallet, especially for automatic printers dealing with high volumes of prints.

- There are various cleaning products available in the market specifically designed for cleaning the top pallet of a heat press.

- Removing lint and residue regularly will ensure a clean and smooth top pallet surface for optimal heat transfer applications.

Importance of Cleaning the Top Pallet

Regularly cleaning the top pallet of a heat press is crucial for maintaining its functionality and ensuring the longevity of the equipment. Accumulated ink, adhesive, and lint can affect the heat transfer process and lead to poor print results. By following proper cleaning techniques, you can maximize the performance of your heat press and prolong its lifespan.

Proper maintenance and cleaning of the top pallet are essential to optimize your heat press’s performance and ensure consistent, high-quality prints. Neglecting regular cleaning can result in ink and residue buildup, causing transfer and image quality issues. Additionally, accumulated lint can affect the adhesion of the print substrate, compromising the print’s durability and finish.

Cleaning the top pallet not only improves the quality of your prints but also prevents damage to the equipment. Over time, ink and adhesive residue can harden and affect the smoothness of the pallet surface, potentially leading to scratches or abrasions on the print substrate. By keeping the top pallet clean, you can minimize the risk of damage and prolong the lifespan of your heat press.

To maintain the top pallet, a regular cleaning routine is recommended. This should include both preventive measures, such as using pallet tape, as well as effective cleaning techniques. Implementing these practices will ensure that your heat press performs optimally and consistently delivers top-notch prints.

Benefits of Cleaning the Top Pallet

| Benefits | Description |

|---|---|

| Enhanced print quality | Cleaning the top pallet removes ink and residue that can affect print quality, resulting in crisper and more vibrant prints. |

| Extended equipment lifespan | Regular cleaning prevents the accumulation of hardened residue, reducing the risk of damage and extending the life of your heat press. |

| Optimized heat transfer | A clean top pallet ensures proper heat distribution, allowing for consistent and accurate transfer of designs onto the print substrate. |

| Reduced substrate contamination | By removing lint and adhesive residue, you minimize the chances of substrate contamination and ensure a smoother finish on your prints. |

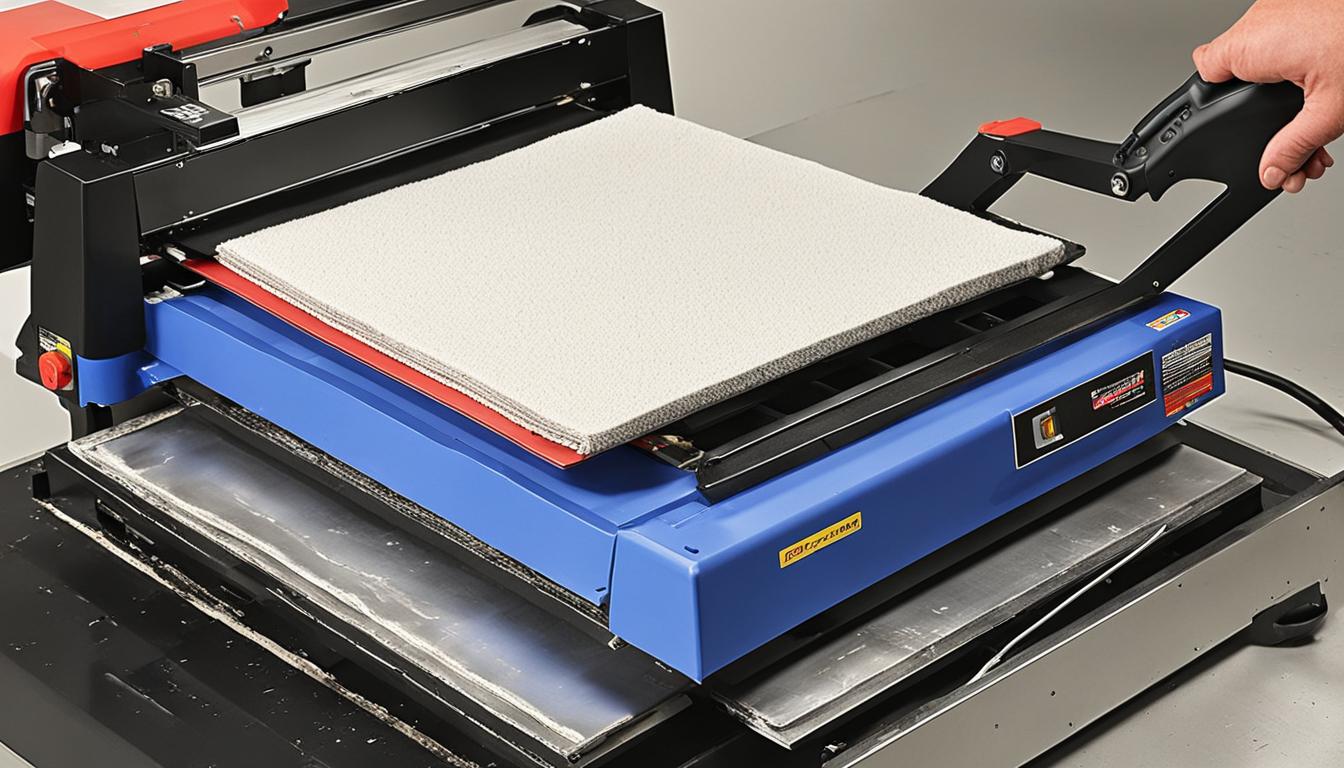

Using Pallet Tape for Easy Cleaning

One effective way to care for the top pallet of a heat press and keep it clean is by using pallet tape. Pallet tape acts as a protective barrier between the pallet and the print substrate, preventing ink, adhesive, and lint from adhering to the surface.

By regularly applying pallet tape and replacing it when it becomes dirty or worn out, you can significantly reduce the cleaning effort required to keep your top pallet clean and ready for high-quality prints. Pallet tape is easy to use and provides a simple maintenance practice that can extend the lifespan of your heat press equipment.

“Using pallet tape is a game-changer for heat press operators. It not only protects the top pallet from ink and adhesive residue but also makes the cleaning process much easier. I highly recommend incorporating this simple yet effective technique into your heat press maintenance routine.”

– Sarah Johnson, experienced heat press operator

When applying pallet tape, make sure to cover the entire top surface of the pallet. This will create a clean and smooth printing area, free from any contaminants that may affect the heat transfer process. The pallet tape should be securely adhered to the pallet to provide optimal protection.

Additionally, regularly inspect the pallet tape for any signs of wear or damage. If you notice any tears or lifting edges, it’s time to replace the tape. Using clean and intact pallet tape ensures the best results and minimizes the risk of ink or adhesive residue transferring onto your prints.

In combination with other cleaning techniques and practices, using pallet tape can enhance the longevity and performance of your heat press top pallet. It provides a proactive solution for keeping your equipment clean and maintaining the quality of your prints.

Benefits of Using Pallet Tape:

- Prevents ink, adhesive, and lint from sticking to the top pallet

- Reduces the need for extensive cleaning and maintenance

- Creates a clean and smooth surface for optimal heat transfer

- Protects the pallet from wear and tear

- Easy to apply and replace

By incorporating pallet tape into your heat press top pallet care routine, you can ensure that your prints are of the highest quality and minimize the maintenance required to keep your equipment in top shape. It’s a small investment that goes a long way in preserving the performance and longevity of your heat press.

| Pros | Cons |

|---|---|

| Protects the top pallet from ink and adhesive residue | Requires regular inspection and replacement |

| Reduces cleaning effort and maintenance time | May require additional cost for purchasing pallet tape |

| Ensures a clean and smooth printing surface | Does not address other potential contaminants on the pallet |

On-Press Wash for Removing Ink and Adhesive

An effective method for cleaning the top pallet of a heat press is through an on-press wash. This technique allows you to remove ink and adhesive buildup without the need to disassemble the equipment. It is particularly beneficial for automatic printers dealing with high volumes of prints.

To begin the cleaning process, wipe off any accumulated lint, ink, or adhesive with a wet rag. Ensure that you cover the entire surface of the top pallet. This preliminary step will make the subsequent cleaning more efficient.

Next, use a flash dryer to dry the pallet quickly. The heat from the dryer will help evaporate any remaining moisture and ensure that the pallet is ready for the next printing job. It’s important to dry the pallet thoroughly to prevent any potential damage to future prints.

This on-press wash technique is not only convenient but also efficient. It allows you to maintain a clean top pallet throughout the production process, ensuring optimal print quality and reducing downtime for extensive cleaning sessions.

Benefits of an On-Press Wash

An on-press wash offers several advantages for cleaning the top pallet:

- Time-saving: Instead of disassembling the heat press for cleaning, an on-press wash allows you to clean the top pallet quickly and efficiently, reducing downtime.

- Prevents ink transfer: By removing ink buildup, you eliminate the risk of accidental ink transfer onto future prints, ensuring clean and precise designs.

- Convenience: With an on-press wash, you can easily incorporate the cleaning process into your regular printing workflow, minimizing disruptions to your production schedule.

Implementing an on-press wash as part of your cleaning routine will help maintain a clean and functional top pallet, resulting in consistent and high-quality print outputs.

Best Practices for On-Press Wash

Follow these best practices to ensure effective cleaning through an on-press wash:

- Regularly inspect the top pallet for any signs of ink or adhesive buildup and clean it promptly to prevent the accumulation of residues.

- Use a damp rag with the appropriate cleaning solution to wipe off the pallet surface thoroughly. This will aid in the removal of stubborn ink and adhesive.

- Always dry the pallet completely before engaging in the next printing job to prevent any moisture-related issues that may affect the print quality.

- Take care not to apply excessive pressure when wiping the pallet, as it can potentially damage the surface.

By implementing these best practices, you can ensure optimal cleaning results and prolong the lifespan of your heat press equipment.

Cleaning Products for Heat Press Top Pallet

When it comes to maintaining the top pallet of a heat press, using the right cleaning products is essential. These specialized products are designed to effectively remove stubborn ink, adhesive, and lint buildup, ensuring a clean and well-functioning top pallet. Here are some popular cleaning products that you can consider:

- Screen wash: A screen wash is a solvent-based cleaner that is specifically formulated for removing ink and adhesive residue. It is easy to use and highly effective in cleaning the top pallet of a heat press. Simply apply the screen wash to the pallet, let it sit for a few minutes, then wipe it off with a clean cloth or sponge.

- Mineral spirits: Mineral spirits are commonly used for cleaning and degreasing surfaces. They can be an effective option for removing ink and adhesive from the top pallet. Apply the mineral spirits to a cloth or sponge and gently scrub the pallet surface until the residue is removed.

- Specialized adhesive removers: There are adhesive removers specifically designed for heat press top pallet cleaning. These removers are formulated to dissolve and remove adhesive residues without damaging the surface. Follow the instructions provided by the manufacturer for the best results.

It is important to note that when using these cleaning products, proper safety precautions should be taken. Ensure you are in a well-ventilated area and avoid direct contact with the skin or eyes. Always read and follow the manufacturer’s instructions for safe and effective use.

Keeping the top pallet of your heat press clean is crucial for maintaining its performance and achieving high-quality prints. By using the right cleaning products and following proper cleaning techniques, you can ensure that your heat press remains in optimal condition and delivers consistent results.

Alternative Cleaning Methods

While pallet tape and cleaning products are effective for cleaning the top pallet of a heat press, there are alternative cleaning methods that you can try. These methods may require a bit more manual effort but can be useful in specific situations or personal preferences.

Using Foam Rollers or Adhesive Applicators

Some heat press operators recommend using foam rollers or adhesive applicators to spread adhesive evenly on the pallet. This technique ensures that the adhesive covers the entire surface and helps in maintaining a clean pallet. By spreading the adhesive evenly, you can prevent ink and lint from sticking directly to the pallet, making it easier to clean later on.

Utilizing Solvents like Goo Gone or Tex-Tac

Another alternative cleaning method is to use solvents like Goo Gone or Tex-Tac water-based liquid adhesive. These solvents are effective in removing stubborn ink, adhesive, and lint buildup on the top pallet. Apply a small amount of solvent to a clean cloth and gently rub the surface of the pallet to dissolve and remove any residue. Make sure to follow the manufacturer’s instructions when using solvents and work in a well-ventilated area.

Tip: Always test solvents on a small, inconspicuous area of the pallet first to ensure they do not damage or discolor the surface.

Remember, alternative cleaning methods may work differently for each heat press model, so it’s essential to experiment and find the method that works best for you. Additionally, it’s crucial to follow the manufacturer’s guidelines and prioritize safety when attempting any cleaning technique.

| Alternative Cleaning Methods | Pros | Cons |

|---|---|---|

| Using foam rollers or adhesive applicators | – Even application of adhesive | – Requires more manual effort |

| Utilizing solvents like Goo Gone or Tex-Tac | – Effective in removing stubborn buildup | – Some solvents may have strong odors |

Removing Lint and Residue

A common issue with the top pallet of a heat press is the accumulation of lint and residue. This can negatively impact print quality and cause transfer issues. To ensure a clean and smooth top pallet surface, it is important to regularly remove lint and residue using the following steps:

- Begin by preparing a solvent cleaner or a solution of water and adhesive.

- Apply the cleaner or solution to the pallet, ensuring to cover the areas with lint and residue.

- Allow the cleaner or solution to sit on the pallet for a while to loosen the lint and residue.

- Gently scrape away the loosened lint and residue using a soft spatula or a cloth.

By regularly removing lint and residue from the top pallet of your heat press, you can maintain its cleanliness and prevent any issues that may arise from the accumulation of debris. Remember to always follow the manufacturer’s cleaning guidelines for your specific heat press model.

If necessary, repeat the cleaning process until all lint and residue are removed. This will ensure that your heat press is ready for high-quality printing and minimize any potential transfer problems caused by debris. Keeping your top pallet clean and free from obstructions will contribute to consistent and professional printing results.

Reactivating Water-Based Adhesive

If you are using water-based adhesive on your top pallet, you have the advantage of being able to reactivate it. This means that if the adhesive loses its tackiness over time, you can reactivate it by misting the pallet with water and applying heat with a flash dryer. Regularly reactivating water-based adhesive can prolong its effectiveness and reduce the need for frequent replacement.

When water-based adhesive starts losing its adhesiveness, it can hinder the quality of your heat transfers. However, reactivating the adhesive is a simple and effective solution to restore its stickiness and ensure successful prints.

“Reactivating water-based adhesive keeps it sticky and ready for use. It’s a cost-effective way to maintain the performance of your heat press top pallet.”

To reactivate water-based adhesive on your top pallet, follow these steps:

- Mist the pallet with water using a spray bottle. Make sure to distribute the mist evenly across the adhesive surface.

- Apply heat to the pallet using a flash dryer or heat press. The heat will activate the water in the mist, causing it to evaporate and reactivate the adhesive.

After reactivating the adhesive, allow the pallet to cool down before using it for heat transfers. The adhesive should regain its tackiness, providing a secure bond between the substrate and the pallet.

By regularly reactivating water-based adhesive, you can extend its lifespan and maintain consistent print quality. This technique is particularly beneficial for heat press operators who frequently use water-based adhesive and want to minimize material waste and replacement costs.

Conclusion

Cleaning the top pallet of a heat press is crucial for maintaining the performance and longevity of your equipment. By following the tips and techniques mentioned in this guide, you can ensure that your heat press operates optimally, producing high-quality prints consistently.

Regular cleaning is key to preventing ink, adhesive, and lint buildup on the top pallet. Consider using pallet tape as a protective barrier and replace it when necessary to keep the surface clean and ready for heat transfer applications.

Additionally, using appropriate cleaning products specifically designed for heat press top pallets can effectively remove stubborn ink, adhesive, and lint. Ensure you follow the instructions provided by the manufacturer and use these products in a well-ventilated area for safety.

Remember to always consult the manufacturer’s guidelines for your heat press equipment and prioritize safety during the cleaning process. By implementing these maintenance tips and cleaning practices, you can maximize the longevity and performance of your heat press, ensuring high-quality prints and a smooth workflow.

FAQ

How often should I clean the top pallet of a heat press?

It is recommended to clean the top pallet of a heat press regularly to prevent ink, adhesive, and lint buildup. The frequency of cleaning depends on the amount of printing you do, but it is generally recommended to clean it after every print run or at least once a day.

What is the best way to clean the top pallet of a heat press?

One effective way to clean the top pallet of a heat press is by using pallet tape. Apply pallet tape regularly and replace it when it becomes dirty or worn out. Additionally, you can use an on-press wash with liquid adhesive, or use specialized cleaning products designed for heat press top pallets.

Can I use a solvent cleaner to remove lint and residue from the top pallet?

Yes, a solvent cleaner can be used to remove lint and residue from the top pallet of a heat press. Apply the cleaner to the pallet, let it sit for a while, and then gently scrape away the lint and residue with a soft spatula or cloth.

How can I reactivate water-based adhesive on the top pallet?

If you are using water-based adhesive on your top pallet, you can reactivate it by misting the pallet with water and applying heat with a flash dryer. This reactivates the adhesive, making it sticky again and ready for use.

Are there alternative cleaning methods for heat press top pallets?

Yes, there are alternative cleaning methods for heat press top pallets. Some operators recommend using foam rollers or adhesive applicators to spread adhesive evenly on the pallet. Others suggest using solvents like Goo Gone or Tex-Tac water-based liquid adhesive for effective cleaning.

How does pallet tape help in keeping the top pallet clean?

Pallet tape acts as a barrier between the pallet and the print substrate, preventing ink, adhesive, and lint from sticking to the surface. By applying pallet tape regularly and replacing it when necessary, you can reduce the cleaning effort and keep your top pallet clean for high-quality prints.