When it comes to heat press care, cleaning and maintaining your Teflon sheet is crucial. Not only does it ensure the durability of your sheet, but it also helps maintain the quality of your prints. Whether you’re a seasoned heat press operator or just starting out, knowing how to clean your Teflon sheet effectively is a skill worth mastering.

In this article, I will provide you with step-by-step instructions on how to clean your Teflon sheet for the heat press. Additionally, I will share some useful tips and hacks to make the cleaning process easier and more efficient.

Before we dive into the cleaning methods, let’s take a moment to understand why cleaning your heat press, especially the Teflon sheet, is so important.

Key Takeaways:

- Regularly cleaning your Teflon sheet helps maintain the quality of your prints and ensures the longevity of your sheet.

- Using a mixture of mild soap and warm water is the most common and effective method for cleaning a Teflon sheet.

- For more stubborn stains, such as sublimation ink or HTV residue, mineral spirits can be used as a stronger cleaning agent.

- Proper drying and storage of the Teflon sheet are crucial to prevent damage and ensure its effectiveness.

- Following best practices for heat press maintenance, such as working in a clean area and protecting the bottom platen, can help prevent stains and prolong the lifespan of your Teflon sheet.

Why Clean Your Heat Press?

Keeping your heat press clean is of utmost importance for maintaining the quality of your prints and the longevity of your machine. Regular cleaning ensures that sticky marks, adhesive transfer, and ink smudges do not affect the outcome of your prints. By prioritizing the cleanliness of your heat press, you can achieve better results and enhance the overall efficiency of your machine.

Cleaning your heat press has numerous benefits. Firstly, it improves the print quality by preventing any unwanted marks or smudges from transferring onto your materials. Clean heat press surfaces ensure that your prints come out crisp and flawless, enhancing the overall appeal of your products.

Additionally, regular cleaning helps to prevent any build-up of ink, adhesives, or other substances on your heat press. These residues can affect the functionality and performance of your machine over time. By keeping your heat press clean, you can avoid any potential damage or malfunctions, ultimately prolonging its lifespan.

Furthermore, when you clean your heat press regularly, you create a clean and hygienic workspace. A clean work environment not only contributes to the quality of your prints but also promotes a professional image to your customers.

Overall, the benefits of cleaning your heat press cannot be emphasized enough. It not only enhances the quality of your prints but also ensures the longevity and efficiency of your heat press machine. By maintaining a clean heat press, you can deliver exceptional results and provide your customers with the best possible products.

What to Use for Cleaning Your Heat Press?

When it comes to cleaning your heat press, it’s important to use the right products and techniques to ensure effective and safe maintenance. Here are some options you can consider:

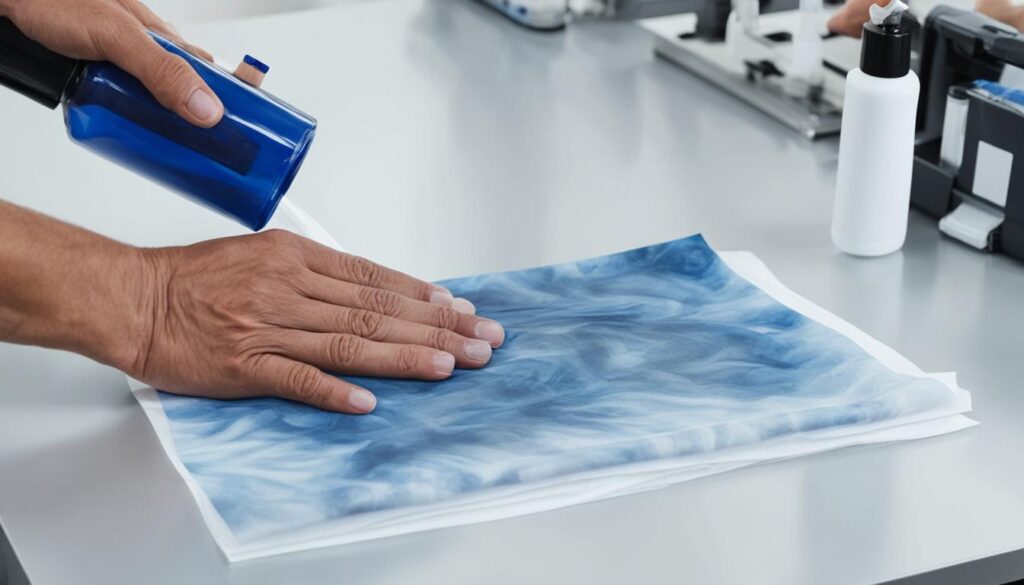

Mild Soap and Warm Water

The most common and effective method for cleaning a heat press is to use a mixture of mild soap and warm water. This gentle solution can effectively remove dirt and ink stains from your machine without causing any damage.

Mineral Spirits

In some cases, you may encounter stubborn oil-based stains on your heat press. In these situations, using mineral spirits can be an effective cleaning solution. Apply a small amount of mineral spirits to a clean cloth and gently rub the stained area. Be sure to follow the manufacturer’s instructions and use the product in a well-ventilated area.

Heat Press Cleaning Products

There are also specific heat press cleaning products available in the market that are designed to remove stains and residue effectively. These products are formulated to be safe for use on heat presses and can provide excellent results when used according to the instructions.

Remember to always refer to your heat press manufacturer’s guidelines and recommendations for cleaning products. They may have specific recommendations or restrictions to ensure the longevity and performance of your machine.

| Cleaning Solution | Pros | Cons |

|---|---|---|

| Mild soap and warm water |

|

|

| Mineral spirits |

|

|

| Heat press cleaning products |

|

|

Remember to always follow the manufacturer’s instructions when using any cleaning solution and test it on a small, inconspicuous area of your heat press before applying it to larger surfaces. Regular cleaning and maintenance using the appropriate cleaning solutions will help keep your heat press in good condition and ensure the longevity of your machine.

Step-by-Step Guide to Cleaning Your Teflon Sheet

Cleaning your Teflon sheet for the heat press is a straightforward process that requires a few essential steps. By following this step-by-step guide, you can effectively clean and maintain your Teflon sheet and ensure optimal performance for your heat press.

Gather the necessary materials:

- Warm water

- Mild soap

- Soft cloth or sponge

- Mineral spirits (optional)

- Clean towel or paper towels

To begin cleaning your Teflon sheet, you’ll need to:

- Remove the Teflon sheet from the heat press and place it on a flat surface.

- Prepare a cleaning solution by mixing warm water and a small amount of mild soap in a bowl or sink.

- Using a soft cloth or sponge, dip it into the cleaning solution and gently scrub the Teflon sheet in circular motions. Pay extra attention to any visible stains or dirt.

- Rinse the sheet thoroughly with clean water to remove any soap residue.

- If there are stubborn stains that the soap solution couldn’t remove, you can try using mineral spirits. Apply a small amount to a clean cloth and gently rub the stained areas. Be cautious not to use too much mineral spirits as it may damage the Teflon surface.

- Once the cleaning process is complete, use a clean towel or paper towels to pat the Teflon sheet dry. Avoid using excessive force or rubbing, which could damage the sheet.

Tip: It’s important to allow the Teflon sheet to dry completely before using it again. This prevents any moisture from affecting your prints or causing damage to the heat press machine.

By following these step-by-step instructions, you can effectively clean your Teflon sheet and maintain its quality for long-lasting use. Remember, regular cleaning and proper maintenance are key to ensuring optimal performance and print results from your heat press.

Cleaning Tips for Teflon Sheets

Proper cleaning and maintenance of your Teflon sheets are essential for preventing stains and ensuring their longevity. Follow these expert tips to keep your Teflon sheets in excellent condition:

1. Use a Teflon Sheet During Heat Pressing

Placing a Teflon sheet between your heat press and the project material provides a protective barrier. This helps prevent any ink or adhesive from transferring onto the Teflon sheet, keeping it clean and prolonging its lifespan.

2. Double-Check Transfers Before Pressing

Before placing your transfer onto the heat press, ensure there are no loose threads, debris, or excess ink. These impurities can cause stains on the Teflon sheet during the pressing process. Taking a moment to double-check can save you from unnecessary cleaning later.

3. Work in a Clean Area

Creating a clean and organized workspace is crucial when working with Teflon sheets. Keep your surrounding area free from dirt, dust, and other contaminants that can adhere to the Teflon surface. This will help prevent stains and maintain the quality of your prints.

4. Protect the Bottom Platen of the Heat Press

The bottom platen of your heat press is vulnerable to stains and residue buildup. To safeguard it, place a Teflon sheet or a non-stick cover over the platen. This extra layer ensures easy cleaning and protects the platen from any potential damage.

By following these cleaning tips, you can safeguard your Teflon sheets and enjoy their benefits for a longer period. Implementing these best practices will not only maintain the cleanliness of your Teflon sheets but also contribute to the overall quality of your heat press projects.

| Cleaning Tips for Teflon Sheets |

|---|

| Use a Teflon Sheet During Heat Pressing |

| Double-Check Transfers Before Pressing |

| Work in a Clean Area |

| Protect the Bottom Platen of the Heat Press |

Cleaning a Teflon Sheet with Sublimation Ink and HTV Stains

Removing sublimation ink and HTV stains from your Teflon sheet requires specific cleaning methods. Understanding the type of stain and using the appropriate cleaning technique is crucial for effective stain removal. Follow these step-by-step instructions to remove sublimation ink and HTV stains from your Teflon sheet.

Materials Needed:

- Heat press machine

- Cotton cloth

Step 1: Heat Transfer Method

- Place the stained Teflon sheet on a flat surface.

- Set the heat press machine to the lowest temperature suitable for the specific type of stain. Refer to the sublimation ink or HTV manufacturer’s guidelines for temperature recommendations.

- Place the cotton cloth on top of the stained area.

- Apply heat using the heat press machine for a short duration. Start with 5-10 seconds and adjust the time accordingly based on the stain’s severity.

- Remove the cotton cloth and check if the stain has transferred onto it.

Step 2: Repeating the Process

If the stain hasn’t completely transferred to the cotton cloth, repeat step 1 multiple times until the stain is no longer visible on the Teflon sheet.

It is important to note that some stains may require additional cleaning techniques such as using a cleaning solution or solvent specifically designed for removing sublimation ink or HTV stains. Always refer to the manufacturer’s recommendations and test any cleaning solution on a small, inconspicuous area of the Teflon sheet before applying it to the stain.

By following these steps and utilizing the appropriate cleaning methods, you can effectively remove sublimation ink and HTV stains from your Teflon sheet, ensuring its longevity and maintaining its quality.

Tips for Maintaining and Storing Your Heat Press

Proper maintenance and storage are essential for ensuring the longevity and optimal performance of your heat press. By following these tips, you can keep your heat press clean, protected from rust, and well-lubricated, ultimately prolonging its lifespan.

1. Keep it Clean

Regular cleaning is crucial to prevent dirt, dust, and residue from accumulating on your heat press. After each use, wipe down the machine with a mild soap and warm water solution. Pay extra attention to the platen, as it comes in contact with the transfers and may accumulate adhesive or ink.

2. Protect it from Rust

Rust can significantly damage your heat press. To prevent this, it’s important to keep your machine dry and protect it from excessive moisture. After cleaning, ensure that all parts are completely dry before storing. For added protection, consider using a dehumidifier in your storage area to control moisture levels.

3. Lubricate Moving Parts

To ensure smooth operation and prevent wear and tear on moving parts, lubrication is key. Apply a thin layer of heat-resistant lubricant, such as silicone oil or sewing machine oil, to the hinges, springs, and other movable components. Be sure to follow the manufacturer’s instructions for the appropriate lubricant to use and frequency of application.

4. Store Properly

When it comes to storing your heat press, it’s important to keep it in a clean and controlled environment. Store it in a dry area away from direct sunlight, extreme temperatures, and humidity. If possible, cover it with a dust cover to protect it from dust and debris.

5. Regularly Inspect and Maintain

Regularly inspect your heat press for any signs of wear, loose screws or bolts, or malfunctioning parts. Addressing these issues promptly can prevent further damage and improve overall performance. Additionally, refer to the manufacturer’s manual for any specific maintenance tasks recommended for your heat press model.

By implementing these maintenance and storage tips, you can ensure that your heat press remains in optimal condition, maximizing its lifespan and producing top-quality prints for years to come.

Best Practices for Heat Press Cleaning and Maintenance

Proper cleaning and maintenance of your heat press machine are crucial for achieving high-quality prints and ensuring its longevity. By following these best practices, you can keep your heat press in optimal condition and run a successful heat press business.

1. Use a Teflon Sheet

When heat pressing, always use a Teflon sheet between the upper platen and the transfer material. This protective sheet prevents any ink or adhesive from transferring onto the heat press, making cleaning a much easier task. The Teflon sheet acts as a barrier, keeping your heat press clean and extending its lifespan.

2. Double-Check Transfers

Prior to pressing, double-check your transfers to ensure they are clean and free of any debris or loose particles. This extra attention to detail will prevent any unwanted substances from coming into contact with your heat press, reducing the need for frequent cleaning. Remember, prevention is key to saving time and effort in the long run.

3. Work in a Clean Area

Keep your workspace clean and organized. A clutter-free environment minimizes the risk of dirt, dust, or other contaminants getting onto your heat press. Regularly wipe down your work surface and surrounding area to maintain cleanliness and avoid any unwanted substances from affecting your prints.

4. Conduct Test Presses

Before starting a production run, perform test presses on scrap material or extra fabric. This step allows you to identify any potential issues or inconsistencies in your heat press machine. By addressing these issues early on, you can prevent damage to your transfers and ensure consistent, high-quality results.

5. Follow Manufacturer’s Guidelines

Refer to the manufacturer’s guidelines for cleaning and maintenance instructions specific to your heat press machine. Each model may have different requirements, so it is important to follow the recommended procedures to avoid any unnecessary damage or void warranty. Adhering to these guidelines will help you prolong the life of your heat press machine.

Incorporating these best practices into your heat press cleaning and maintenance routine will save you time, effort, and money in the long run. By keeping your machine clean and well-maintained, you can consistently produce high-quality prints and optimize the performance of your heat press.

| Benefits of Best Practices | Cleaning and Maintenance Techniques |

|---|---|

| – Improved print quality | – Regularly wipe down the heat press surfaces |

| – Extended lifespan of the heat press machine | – Use mild soap and warm water for routine cleaning |

| – Reduced downtime for maintenance | – Utilize a Teflon sheet to protect the upper platen |

| – Cost savings in replacement and repairs | – Double-check transfers before pressing |

| – Consistent and reliable performance | – Conduct test presses to identify issues |

Conclusion

In conclusion, proper cleaning and maintenance of your Teflon sheet and heat press are crucial for achieving high-quality prints and ensuring the longevity of your machine. By following the provided tips and techniques, you can effectively clean your Teflon sheet and maintain your heat press in excellent working condition.

Regular cleaning with appropriate methods, such as using mild soap and warm water, helps remove dirt stains and prevents adhesive transfer and ink smudges. It is also important to use cleaning agents like mineral spirits for more stubborn stains. Additionally, implementing best practices like using a Teflon sheet during heat pressing and protecting the bottom platen of your heat press can further enhance the cleanliness and quality of your prints.

Remember, a clean heat press not only improves the efficiency of your machine but also safeguards against common issues that could affect the quality of your prints. By prioritizing maintenance and following the cleaning techniques outlined in this article, you can produce outstanding prints and prolong the lifespan of your heat press, ultimately contributing to the success of your heat press business.

FAQ

How do I clean my Teflon sheet for a heat press?

To clean your Teflon sheet, you can use a mixture of mild soap and warm water. Gently scrub the sheet with a soft cloth or sponge, then rinse it thoroughly and let it air dry. For stubborn stains, you can use mineral spirits or an oven cleaner. Be sure to follow the manufacturer’s instructions and test any cleaning solution on a small, inconspicuous area first.

Why is it important to clean your heat press?

Cleaning your heat press is crucial for preventing sticky marks, adhesive transfer, and ink smudges that can affect the quality of your prints. Regular cleaning also improves the efficiency and longevity of your heat press machine, ensuring it performs at its best.

What can I use to clean my heat press?

The most common and effective cleaning solution for a heat press is a mixture of mild soap and warm water. This combination can remove most dirt and ink stains. For more stubborn stains or oil-based materials, you may need to use a stronger cleaning agent like mineral spirits or an oven cleaner. Always follow the manufacturer’s instructions and test any cleaning solution on a small, inconspicuous area first.

How do I clean my Teflon sheet step-by-step?

1. Prepare a mixture of mild soap and warm water. 2. Dip a soft cloth or sponge into the soapy water and gently scrub the Teflon sheet. 3. Rinse the Teflon sheet thoroughly with clean water. 4. Dry the Teflon sheet with a clean towel or let it air dry. 5. For stubborn stains, apply a small amount of mineral spirits to a clean cloth and gently rub the stained area. 6. Rinse the Teflon sheet again and air dry before using.

What are some cleaning tips for Teflon sheets?

Here are some cleaning tips for Teflon sheets: – Always use a Teflon sheet during heat pressing to protect it from ink and debris. – Double-check your transfers before pressing to ensure there are no excess inks or contaminants that can transfer onto the Teflon sheet. – Work in a clean area to minimize the chance of dirt or debris getting onto the Teflon sheet. – Use a silicone or Teflon cover on the bottom platen of your heat press to protect the Teflon sheet from discoloration or damage.

How do I clean a Teflon sheet with sublimation ink and HTV stains?

To clean a Teflon sheet with sublimation ink stains or HTV stains, place the stained area face down on a heat press machine. Lay a clean cotton cloth on top and press it at a low heat setting for a short duration. The heat and pressure will transfer the stain from the Teflon sheet to the cloth. Repeat the process if necessary, using a clean section of the cloth each time.

What are some tips for maintaining and storing my heat press?

Here are some tips for maintaining and storing your heat press: – Keep your heat press clean by wiping it down regularly with a mild soap and water solution. – Protect your heat press from rust by keeping it in a dry environment and using a rust inhibitor if necessary. – Lubricate the moving parts of your heat press according to the manufacturer’s instructions to ensure smooth operation. – Store your heat press in a clean and dust-free area when it is not in use.

What are the best practices for heat press cleaning and maintenance?

Some best practices for heat press cleaning and maintenance include using a Teflon sheet during heat pressing, double-checking transfers before pressing, working in a clean area, conducting test presses to ensure proper settings, and following the manufacturer’s recommended maintenance procedures. These practices will help you achieve high-quality prints and prolong the lifespan of your heat press.

How important is heat press maintenance?

Heat press maintenance is essential for ensuring the longevity and performance of your machine. Regular cleaning and proper care will help prevent issues such as sticky marks, adhesive transfer, and ink smudges, which can affect the quality of your prints. By following the recommended maintenance procedures, you can keep your heat press in excellent working condition and avoid common problems.