To keep your Stahls heat press performing at its best, proper cleaning and maintenance are essential. In this guide, I will provide you with quick tips on how to effectively clean your Stahls heat press, ensuring optimal functionality and longevity.

Key Takeaways:

- Regular cleaning and maintenance of your Stahls heat press is crucial for optimal performance.

- Test the pressure regularly to ensure even and consistent heat distribution.

- Wipe down the upper platen after each project to remove excess ink and residue.

- Replace cutting strips annually, or more often for high-volume cutting.

- Check the temperature accuracy to ensure consistent heat throughout the platen.

Test the Pressure

Before cleaning your Stahls heat press, it is essential to test the pressure. Proper pressure is crucial for achieving consistent and high-quality results. Here’s how you can test the pressure of your Stahls heat press:

- Place a piece of paper at each corner of the lower platen.

- Lock the platen into place.

- Try to remove the sheets of paper one by one.

If any of the sheets slide out easily, it indicates uneven pressure. In such cases, you will need to adjust the pressure settings of your heat press to ensure even distribution across the entire platen.

Testing the pressure regularly is essential because uneven pressure can lead to inconsistent heat transfers and subpar printing results. By maintaining proper pressure, you can optimize the performance of your Stahls heat press and produce professional-grade designs.

Next, let’s move on to cleaning the upper platen of your Stahls heat press.

Clean Upper Platen

After each project, it is important to wipe down the upper platen of your Stahls heat press. Excess ink, adhesives, and residue can build up and transfer to the next job. Wiping the platen while it is hot with a clean, dry cloth is usually sufficient.

Regular cleaning of the upper platen helps maintain its surface and ensures that it remains free from any contaminants that could affect the quality of your heat transfers. By following these simple cleaning steps, you can keep your Stahls heat press in optimal condition:

- Wait for the heat press to cool down: Before cleaning the upper platen, make sure it has completely cooled down to avoid any burns or injuries.

- Prepare a clean, dry cloth: Use a lint-free cloth or a non-abrasive material to wipe the surface of the platen.

- Wipe the platen: Gently wipe the upper platen in a circular motion, removing any ink, adhesives, or residue. Be thorough in your cleaning, paying attention to the edges and corners.

- Use a mild cleaning solution (if necessary): If there are stubborn stains or residue that cannot be removed with a dry cloth, dampen the cloth with a mild cleaning solution specifically designed for heat press platens. Follow the manufacturer’s instructions and avoid using harsh chemicals or abrasive cleaners.

- Dry the platen: After cleaning, make sure to dry the platen thoroughly with a separate clean, dry cloth. Moisture can affect the performance of the heat press, so it’s crucial to remove any excess liquid.

By regularly cleaning the upper platen of your Stahls heat press, you can ensure that it remains in optimal condition and provides consistent heat transfers. Remember to always follow the manufacturer’s guidelines and recommendations for cleaning and maintenance to prolong the lifespan of your heat press equipment.

Replace Cutting Strips

When it comes to cleaning your Stahls heat press, it’s not just about wiping down the upper platen or checking the temperature accuracy. There are other essential maintenance tasks that you shouldn’t overlook, such as replacing the cutting strips on your vinyl cutter.

The cutting strips play a crucial role in ensuring the optimal performance of your Stahls heat press. Over time, with regular use, the cutting strips can wear out or become damaged. When this happens, it’s important to replace them to maintain the quality of your cuts and prevent any issues during the heat pressing process.

Stahls recommends replacing the cutting strips at least once a year. However, if you’re cutting higher volumes, it may be necessary to replace them more frequently. By doing so, you’ll ensure that your vinyl cutter is functioning at its best, providing clean and precise cuts every time.

Replacing the cutting strips is a relatively straightforward process. Simply follow the instructions provided by the manufacturer of your vinyl cutter. Typically, it involves removing the old cutting strips and replacing them with new ones.

It’s worth mentioning that using worn-out cutting strips can lead to imperfect cuts, which can affect the overall quality of your heat pressing projects. This is why regular maintenance, including the replacement of cutting strips, is vital for keeping your Stahls heat press in top condition.

Remember, expert advice on cleaning your Stahls heat press goes beyond just the basics. Taking the time to replace the cutting strips is a small but essential step in maintaining the performance and longevity of your heat press machine.

Check Temperature Accuracy

To ensure that your Stahls heat press is functioning optimally, it is crucial to regularly check the temperature accuracy. This step is vital as it guarantees that the machine maintains consistent heat and evenly distributes it across the upper platen. A simple and effective way to verify the temperature accuracy is by using a heat press test kit.

The heat press test kit allows you to check the actual temperature of your heat press and compare it to the displayed temperature. This ensures that you are getting accurate results and helps identify any potential issues with the temperature control of your machine.

How to Test Temperature Accuracy:

- Turn on your heat press and let it warm up to the desired operating temperature.

- Place the heat press test kit on the center of the upper platen.

- Close the heat press and apply medium pressure.

- Leave the test kit in the press for the recommended amount of time as per the test kit instructions.

- Open the heat press and carefully remove the test kit.

- Compare the temperature reading on the test kit with the displayed temperature on your machine.

If the temperatures match or are within an acceptable range, your Stahls heat press is functioning accurately. However, if there is a significant difference between the two readings, it may indicate a need for calibration or repair. In such cases, it is recommended to consult the manufacturer’s maintenance guide or contact their customer support for further assistance.

Regularly checking the temperature accuracy of your Stahls heat press ensures that you achieve consistent and reliable heat application, resulting in high-quality and long-lasting transfers. By maintaining proper temperature control, you can avoid issues such as under or over-pressing, scorch marks, or uneven application.

| Benefits of Checking Temperature Accuracy |

|---|

| Ensures consistent heat distribution |

| Prevents under or over-pressing |

| Avoids scorch marks on transfers |

| Promotes even and long-lasting transfers |

By following the step-by-step guide to check the temperature accuracy of your Stahls heat press and incorporating this maintenance task into your regular cleaning routine, you can ensure that your heat press performs at its best and delivers professional results.

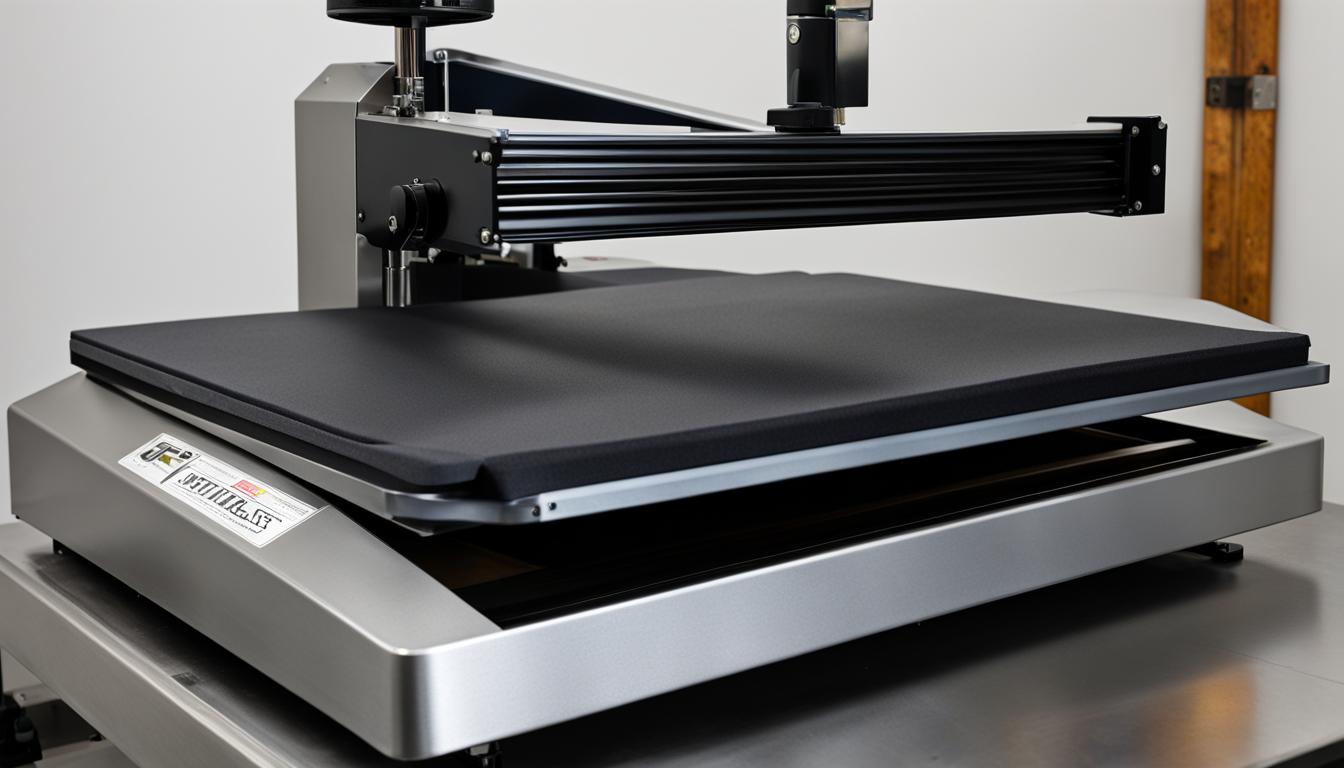

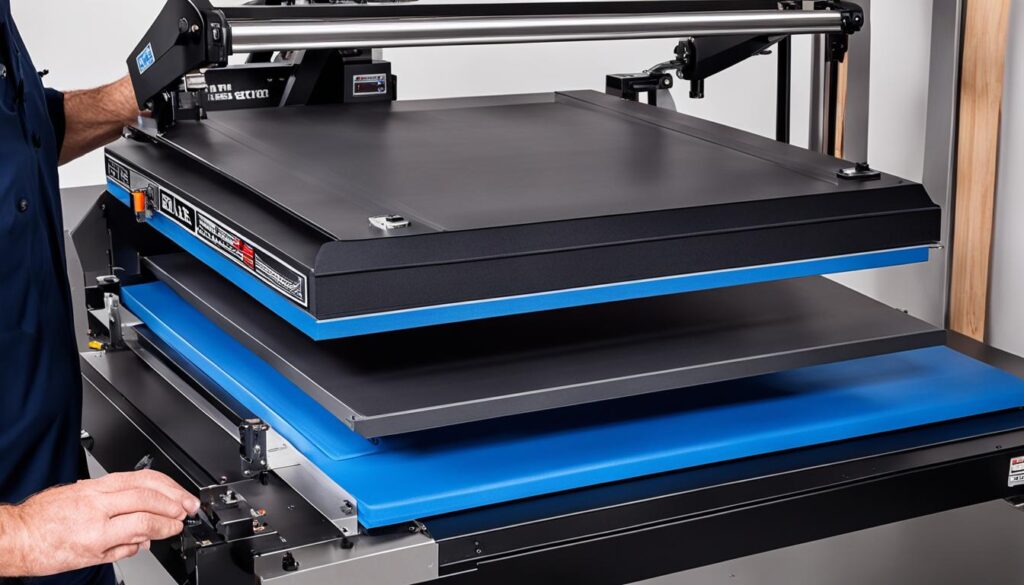

Cover Lower Platen

When it comes to cleaning your Stahls heat press, don’t overlook the importance of protecting the lower platen. Using a Quick Slip Lower Platen Protector can provide multiple benefits, ensuring that your heat press stays in optimal condition.

The Quick Slip Lower Platen Protector is designed to be placed on the lower platen of your Stahls heat press. Its main function is to allow garments to be slipped on and off more quickly, streamlining your workflow and saving you valuable time.

Not only does the Quick Slip Lower Platen Protector enhance efficiency, but it also extends the life of the silicone rubber pad. By acting as a protective barrier, it prevents direct contact between the garments and the platen, reducing wear and tear on the pad. This helps to maintain the overall quality of your heat press and ensures consistent heat distribution.

In addition to extending the lifespan of your heat press, the Quick Slip Lower Platen Protector also helps to protect the platen from any debris or residue. It acts as a shield, preventing ink, adhesives, and other substances from coming into direct contact with the platen’s surface. This not only makes the cleaning process easier but also helps to prevent any potential damage to the platen itself.

Overall, using a Quick Slip Lower Platen Protector is an essential tip for cleaning your Stahls heat press effectively. It not only improves efficiency but also protects both the silicone rubber pad and the platen from unnecessary wear and tear. By incorporating this simple accessory into your cleaning routine, you can ensure that your heat press remains in optimal condition, providing you with consistent and high-quality results.

| Benefits of Using a Quick Slip Lower Platen Protector: |

|---|

| Allows for quick garment insertion and removal |

| Extends the life of the silicone rubber pad |

| Protects the platen from debris and residue |

Use Dedicated 20 Amp Outlet

In order to maintain the optimal performance of your Stahls heat press, it is recommended to use a dedicated 20 amp electrical outlet. By dedicating an outlet specifically for your heat press machine, you can avoid overloading your electrical system and prevent the blowing of fuses.

This proper cleaning practice ensures that your heat press will have a consistent and reliable power supply, which is crucial for achieving the best results. It also minimizes the risk of electrical issues and malfunctions that may occur if the heat press shares an outlet with other appliances.

By adhering to this maintenance guideline, you can protect both your Stahls heat press and your electrical system, ensuring a smooth and efficient operation every time you use your machine.

Benefits of Using a Dedicated 20 Amp Outlet

Here are the key benefits of using a dedicated 20 amp outlet for your Stahls heat press:

- Prevents overloading: By having a dedicated outlet for your heat press, you can avoid overloading the circuit and tripping the circuit breaker.

- Consistent power supply: Having a dedicated outlet ensures that your heat press receives a consistent and uninterrupted power supply, allowing for accurate and efficient operation.

- Enhances safety: By separating your heat press from other electrical appliances, you reduce the risk of electrical hazards and potential accidents.

- Reduces downtime: With a dedicated outlet, you eliminate the need to constantly plug and unplug your heat press, reducing the risk of wear and tear on the power cord and socket.

Overall, using a dedicated 20 amp outlet for your Stahls heat press is a simple and effective maintenance practice that ensures optimal performance, extends the lifespan of your machine, and promotes a safe working environment. Make sure to consult an electrician to ensure that your outlet is properly installed and meets all safety codes and regulations.

| Benefits of Using a Dedicated 20 Amp Outlet |

|---|

| Prevents overloading |

| Consistent power supply |

| Enhances safety |

| Reduces downtime |

Keep a Clean Work Area

When it comes to maintaining a Stahls heat press, cleanliness is key. To ensure optimal results and prevent any unwanted debris from transferring onto your substrate, it’s important to keep your work area and equipment clean. Here are some essential tips for maintaining a clean work environment:

- Before starting a new job, clean the work area thoroughly to remove any lint, hair, or other debris that could potentially contaminate your heat press.

- Make sure to also clean your Stahls heat press before and after each use. This will help prevent any buildup of adhesives, inks, or other residues that could affect the performance of your machine.

- Use a lint roller or a clean, damp cloth to wipe down the workspace and the heat press to remove any loose particles. Pay special attention to the platens and the surrounding areas.

- If you’re working with adhesive-based materials, such as heat transfer vinyl, it’s crucial to keep the work area free from dust and other contaminants. Consider using a clean, dedicated table or surface for heat pressing to minimize the risk of any unwanted particles attaching to the adhesive.

- Regularly inspect and clean the bottom of the heat press to remove any debris that may have accumulated. This will help ensure proper functioning and prevent any damage to the machine.

By maintaining a clean work area, you can ensure that your Stahls heat press operates smoothly and produces high-quality results. Remember, a little cleaning goes a long way in preserving the longevity and performance of your heat press.

Quote:

“A clean work area not only enhances the performance of your heat press but also improves the overall quality of your finished products.” – Stahls

Perform Test Cuts

Regularly performing test cuts is a crucial step in maintaining the efficiency of your Stahls heat press and ensuring high-quality results. Test cuts help determine if the vinyl cutter or print/cut system blade requires replacement. By conducting these tests, you can identify any issues with cutting precision and take appropriate action to resolve them.

When performing test cuts, pay close attention to the quality of the cuts and the condition of the material. If you notice that the material is not being cut through completely or if it has jagged edges, it indicates that the blade needs replacement. Inaccurate cuts can lead to wasted material and inconsistent results in your heat press projects.

To perform test cuts effectively, follow these steps:

- Choose a small and simple design or shape to cut.

- Ensure that the material is properly loaded into the vinyl cutter or print/cut system.

- Adjust the cutting settings following manufacturer’s recommendations.

- Execute the test cut and inspect the results closely.

If the cut is clean and precise, with no jagged edges or uncut areas, your blade is in good condition. However, if the results are not satisfactory, it is time to replace the blade. Continuously monitor the performance of your blade and conduct test cuts regularly to maintain optimal cutting performance in your Stahls heat press.

Quote:

“Regularly performing test cuts not only ensures the longevity of your blade but also guarantees the accurate delivery of your designs onto garments or materials. It’s a small step that makes a big difference in the quality of your heat press projects.”

Troubleshooting Tips:

If you encounter any issues with the test cuts, consider the following troubleshooting tips:

- Check the blade depth to ensure it is properly set for the material being cut.

- Inspect the cutting strip for damage or wear and replace if necessary.

- Clean the blade holder to remove any debris that may be affecting cutting performance.

- Verify that the design or artwork you are cutting is compatible with the material being used.

- Calibrate your vinyl cutter or print/cut system according to the manufacturer’s instructions.

By following these steps and troubleshooting tips, you can maintain the cutting accuracy and efficiency of your Stahls heat press, ensuring consistent and professional results in every project.

Keeping the Heat Press Clean – Tips and Tricks

In addition to the specific cleaning tips mentioned above, here are some general tips and tricks to keep your Stahls heat press clean:

- Keep the working area clean and dust-free to avoid any damage to the electrical components.

- Protect the upper platen from inks and residue by using an Upper Platen Cover and a Non-Stick Cover Sheet.

- Protect the lower platen from wear and tear by using a Quick Slip Lower Platen Protector.

- Grease all exposed rods and threaded pressure adjustment spindles annually.

- Use the original cord that came with the heat press to avoid any safety hazards.

Following these tips and tricks will help you maintain the cleanliness and longevity of your Stahls heat press, ensuring optimal performance and consistent results.

Conclusion

Proper cleaning and maintenance are crucial for ensuring the optimal performance of your Stahls heat press. By following the provided tips and techniques, you can keep your heat press in top condition and consistently produce high-quality results.

Regularly test the pressure of your heat press to ensure even distribution and avoid any printing inconsistencies. Cleaning the upper platen after each project with a clean, dry cloth will prevent the transfer of ink, adhesives, and residue to subsequent jobs.

Additionally, consider replacing cutting strips annually or more frequently if cutting larger volumes. This will help maintain the heat press’s cutting accuracy and prolong its lifespan.

Remember to check the temperature accuracy regularly using a heat press test kit. A dedicated 20 amp outlet is recommended for avoiding electrical overload and potential damage to your heat press.

Creating a clean work area, performing test cuts as needed, and implementing additional protective measures like using covers and protectors will further contribute to the longevity and efficiency of your Stahls heat press.

FAQ

How often should I replace the cutting strips on my Stahls heat press?

Stahls recommends replacing the cutting strips at least once a year or more frequently if cutting higher volumes. This ensures optimal performance of your heat press.

How do I test the pressure of my Stahls heat press?

To test the pressure, place a piece of paper at each corner of the lower platen and lock it into place. Try to remove the sheets of paper, and if any slide out easily, it indicates uneven pressure.

How should I clean the upper platen of my Stahls heat press?

After each project, wipe down the upper platen with a clean, dry cloth. This will remove excess ink, adhesives, and residue that can build up and transfer to the next job.

How can I check the temperature accuracy of my Stahls heat press?

Use a heat press test kit to check the accuracy of the temperature. Ensure that the machine is maintaining heat and heating evenly throughout the upper platen.

Should I use a lower platen protector on my Stahls heat press?

Using a Quick Slip Lower Platen Protector on the lower platen provides multiple benefits. It allows garments to be slipped on and off more quickly, extends the life of the silicone rubber pad, and helps protect the platen from debris or residue.

Is it necessary to use a dedicated 20 amp outlet for my Stahls heat press?

Stahls recommends using a dedicated 20 amp outlet for all heat press machines. This helps to avoid overloading your electrical system and blowing fuses.

How can I ensure a clean work area when using my Stahls heat press?

Before and after every job, clean the work area to avoid transferring lint, hair, and other debris to the substrate when heat pressing any adhesive-based material.

How often should I perform test cuts on my Stahls heat press?

Regularly perform test cuts to determine if the vinyl cutter or print/cut system blade needs replacement. If the material isn’t being cut through or has jagged edges, it indicates that the blade needs replacement.

What are some general tips to keep my Stahls heat press clean?

Keep the working area clean and dust-free, protect the upper platen with an Upper Platen Cover and a Non-Stick Cover Sheet, use a Quick Slip Lower Platen Protector to protect the lower platen, and grease all exposed rods and threaded pressure adjustment spindles annually. Additionally, always use the original cord that came with the heat press.