A heat press machine, such as the Panther Press Heat Press, is a valuable tool for applying prints onto various substrates. To maintain the performance and durability of your Panther Press Heat Press, regular cleaning is essential. In this ultimate guide, I will provide you with expert tips and a maintenance guide to help you clean your Panther Press Heat Press effectively.

When it comes to cleaning your Panther Press Heat Press, there are specific steps and materials you should use to ensure optimal results. By following these guidelines, you can keep your heat press machine in top condition, ensuring high-quality prints and a longer lifespan.

Key Takeaways:

- Regular cleaning is crucial for maintaining the performance and durability of your Panther Press Heat Press.

- Use heat-resistant cleaning solutions and materials designed specifically for heat presses.

- Clean the platen, base, exterior surfaces, and heating element of your heat press machine.

- Lubricate the moving parts and cover the heat press when not in use for extended longevity.

- Always prioritize safety and consult the manufacturer’s instructions for proper cleaning and maintenance.

Why Cleaning Your Panther Press Heat Press is Important

Regularly cleaning your Panther Press Heat Press is crucial for several reasons. Firstly, it helps remove any debris, adhesive residues, or ink buildup that can affect the heat transfer process and result in lower quality prints.

Secondly, proper cleaning prevents the transfer of dirt and contaminants onto your garments or other substrates, ensuring a professional finish. No one wants a beautiful design marred by unwanted specks or smudges.

Additionally, regular maintenance and cleaning help prolong the lifespan of your Panther Press Heat Press, saving you money in the long run. By removing any buildup or residues, you can prevent potential damage to the machine and ensure its optimal performance for years to come.

Take pride in your work and invest the time to keep your Panther Press Heat Press clean and well-maintained. It’s a small effort that goes a long way in producing high-quality prints and preserving the longevity of your valuable equipment.

| Benefits of Cleaning Your Panther Press Heat Press |

|---|

| 1. Ensures optimum heat transfer and print quality |

| 2. Prevents the transfer of dirt and contaminants onto your prints |

| 3. Prolongs the lifespan of your Panther Press Heat Press |

| 4. Saves money by avoiding costly repairs or replacements |

Cleaning Supplies and Materials Needed

Before you begin cleaning your Panther Press Heat Press, it’s important to gather the necessary cleaning supplies and materials. Having the right tools will help you efficiently and effectively clean your heat press, ensuring its optimal performance and longevity.

Here are the essential cleaning supplies and materials you’ll need:

- Lint-free cloth or sponge: This will be used to wipe and clean various parts of your heat press, ensuring no lint or residue is left behind.

- Heat-resistant cleaning solution or spray: Use a cleaning solution or spray specifically designed for heat presses. This will help remove adhesive residues, ink buildup, and other contaminants.

- Silicone lubricant or heat press cover: Applying silicone lubricant to the moving parts of your heat press will keep them functioning smoothly. Alternatively, using a heat press cover will protect the machine from dust and other contaminants when not in use.

- Soft brush or cotton swabs: These tools are essential for reaching and cleaning hard-to-reach areas of your heat press, ensuring thorough cleaning.

Remember to use cleaning solutions and materials specifically designed for heat presses. Using improper cleaning agents can damage the machine and affect its performance.

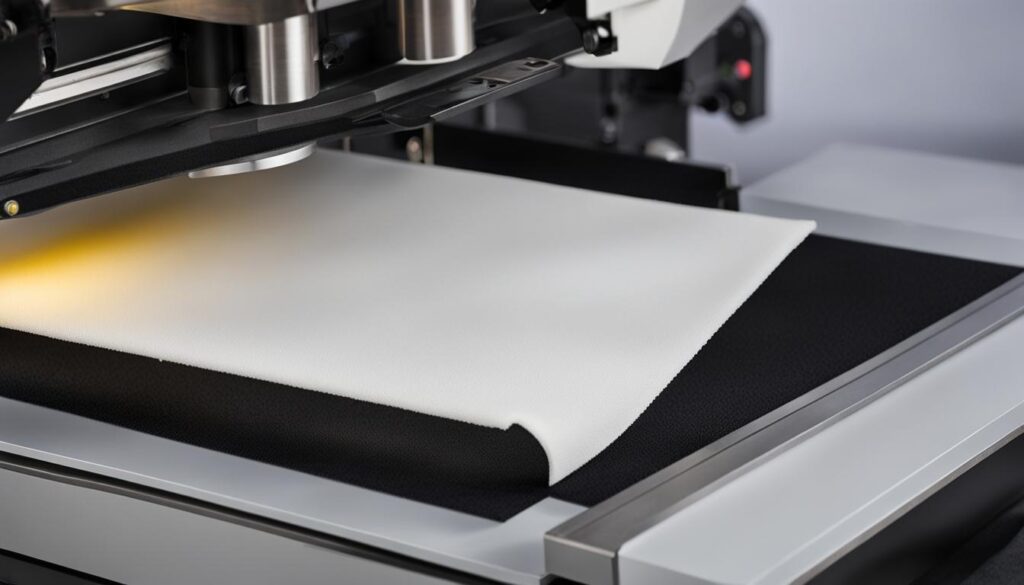

To give you a visual idea of the necessary cleaning supplies and materials, here’s an image:

Please note: The image is for illustrative purposes only and may not depict the exact brands or products mentioned.

Now that you have your cleaning supplies and materials ready, let’s move on to the cleaning process for each part of your Panther Press Heat Press.

Cleaning the Platen

The platen is a crucial component of your Panther Press Heat Press that requires regular cleaning to ensure optimal performance. The platen is the top surface of the heat press machine that directly contacts your transfers and substrates. To keep the platen clean and free from adhesive residue or ink buildup, follow these simple steps:

- Disconnect the heat press from the power source and allow it to cool down completely. Safety is a priority, so don’t skip this step.

- Dampen a lint-free cloth or sponge with a heat-resistant cleaning solution specifically designed for heat presses.

- Gently wipe the platen using the cloth or sponge, making sure to remove any adhesive residue or ink buildup. Apply light pressure when necessary.

- For stubborn stains, use a soft brush or cotton swab to gently scrub the affected area. Be careful not to scratch or damage the platen.

- After cleaning, wipe the platen with a clean, dry cloth to remove any excess moisture. This step helps prevent the buildup of moisture that may affect future print jobs.

Remember to always handle the platen with care and avoid using abrasive materials that could damage its surface. With regular cleaning and maintenance, your Panther Press Heat Press platen will provide consistent heat distribution and ensure high-quality prints.

Expert Tip:

To maintain the cleanliness and functionality of your Panther Press platen, consider using a platen cover or protective sheet during heat transfer applications. This extra layer of protection helps minimize direct contact between the platen and transfers, reducing the chances of adhesive residue or ink buildup.

Summary

Cleaning the platen of your Panther Press Heat Press is a crucial step in maintaining its performance and prolonging its lifespan. By following the recommended cleaning process, you can ensure that your platen remains free from adhesive residue, ink buildup, and other contaminants, allowing for consistent heat distribution and high-quality prints. Remember to handle the platen with care and consider using a platen cover or protective sheet for added protection. With regular cleaning and maintenance, your Panther Press Heat Press will continue to deliver excellent results for all your heat transfer projects.

Cleaning the Base and Exterior Surfaces

Properly cleaning the base and exterior surfaces of your Panther Press Heat Press is essential to maintain its performance and longevity. Follow these steps to ensure a thorough cleaning process:

- Start by unplugging the machine and allowing it to cool down completely. This step is crucial for your safety and preventing any damage to the heat press.

- Once the machine has cooled, use a lint-free cloth or sponge dampened with a heat-resistant cleaning solution to wipe the base and exterior surfaces. This will help remove any dust, dirt, or debris that may have accumulated over time.

- When cleaning, pay extra attention to button areas, control panels, and any other crevices or hard-to-reach areas where contaminants might be present. Use a soft brush or cotton swab to ensure a thorough cleaning.

- Avoid getting excessive moisture into electrical components to prevent any potential damage. Wipe the surfaces with a clean, dry cloth after cleaning to remove any excess moisture.

Cleaning the base and exterior surfaces of your Panther Press Heat Press not only enhances its appearance but also helps maintain its functionality. By following these cleaning steps regularly, you can ensure that your heat press performs optimally and lasts for years to come.

Recommended Cleaning Schedule:

For optimal results, it is recommended to clean the base and exterior surfaces of your Panther Press Heat Press after each use or at least once every two weeks, depending on your usage frequency.

| Step | Description |

|---|---|

| Step 1 | Unplug the machine and allow it to cool down. |

| Step 2 | Wipe the base and exterior surfaces with a lint-free cloth or sponge dampened with a heat-resistant cleaning solution. |

| Step 3 | Pay attention to button areas, control panels, and hard-to-reach spots. |

| Step 4 | Avoid excessive moisture and wipe surfaces with a clean, dry cloth. |

Cleaning the Heating Element

The heating element of your Panther Press Heat Press is a crucial component that requires regular cleaning to maintain its efficiency. By keeping the heating element clean, you can ensure optimal performance and prolong the lifespan of your machine.

To start the cleaning process, make sure that your heat press is completely disconnected from the power source and has cooled down. It’s essential to prioritize safety at all times.

Once your heat press is safely disconnected and cooled, you can begin cleaning the heating element. Use a soft brush or cotton swab to gently remove any debris or residue that may have accumulated on the element. Take care not to use harsh or abrasive materials that could potentially damage the heating element.

After removing the debris and residue, wipe the heating element with a clean, dry cloth to ensure that all remaining particles are removed. This step helps to maintain the heating element’s effectiveness and prevent any build-up that could affect the quality of your heat transfers.

Regularly cleaning the heating element of your Panther Press Heat Press is an essential part of proper maintenance. By following this simple cleaning process, you can ensure that your heat press continues to deliver excellent results.

Remember, the heating element plays a crucial role in the performance of your Panther Press Heat Press. By keeping it clean and well-maintained, you can enjoy many years of efficient heat transfer and professional-quality prints.

Lubricating Moving Parts and Maintenance

In addition to regular cleaning, proper lubrication of the moving parts is crucial for maintaining optimal performance and longevity of your Panther Press Heat Press. By applying a small amount of silicone lubricant to the hinges, springs, and other moving components, you can ensure smooth operation and prevent friction that may lead to wear and tear.

Following the manufacturer’s recommendations, identify the specific areas that require lubrication. Apply the silicone lubricant with a cloth or a brush, making sure to cover all the necessary parts. This simple maintenance step will help your Panther Press Heat Press to function at its best, providing consistent and high-quality heat transfers.

To further protect your heat press from dust and other contaminants, consider using a heat press cover when the machine is not in use. This cover acts as a barrier, keeping your Panther Press Heat Press clean and ready for the next application.

Benefits of Proper Lubrication

Lubricating the moving parts of your Panther Press Heat Press offers several benefits:

- Enhanced Performance: The smooth operation provided by proper lubrication ensures that your heat press functions optimally, reducing unnecessary strain on the machine.

- Extended Lifespan: By minimizing friction and wear, lubrication helps prolong the lifespan of components, preventing premature breakdowns and the need for costly repairs.

- Improved Print Quality: With reduced friction, the heat press can maintain a consistent temperature distribution, resulting in sharper and more vibrant heat transfers.

- Cost Savings: Regular lubrication and maintenance can help prevent potential issues, saving you money on repairs and replacement parts.

By incorporating lubrication into your regular maintenance routine, you can ensure that your Panther Press Heat Press operates at its peak performance, providing excellent results with every use.

Remember to consult your Panther Press Heat Press user manual or manufacturer’s guidelines for specific lubrication recommendations and instructions.

Troubleshooting and Common Issues

Despite regular cleaning and maintenance, issues may still arise with your Panther Press Heat Press. It’s important to be aware of common problems and know how to troubleshoot them effectively. Here are some common issues you may encounter:

1. Uneven Heat Distribution

One common issue with heat presses is uneven heat distribution, which can result in inconsistent heating of your transfers. This can lead to subpar prints and wasted materials. To troubleshoot this issue, try the following:

- Ensure that your transfers are placed flat and evenly on the platen.

- Check that the pressure adjustment is properly set according to the thickness of your substrate.

- Verify that the temperature and timer settings are accurate.

- If the issue persists, it may be necessary to have the heat press serviced or calibrated by a professional technician.

2. Temperature Fluctuations

Another common issue is temperature fluctuations, where the heat press fails to consistently maintain the set temperature. To address this problem, consider the following troubleshooting steps:

- Ensure that the heat press is properly connected to a stable power source.

- Check the electrical cords and plugs for any signs of damage or loose connections.

- Verify that the heat press is placed on a stable, level surface.

- Clean the heating element and vents to remove any debris that may be affecting temperature control.

- If the issue persists, contact the manufacturer for further assistance or seek professional repair.

3. Control Panel Issues

Problems with the control panel can occur, preventing proper operation of the heat press. If you experience control panel issues, try the following troubleshooting steps:

- Ensure that the control panel is not exposed to excessive moisture or liquids.

- Check that the buttons and controls are not stuck or damaged.

- Verify that the control panel is properly connected to the main unit.

- If the issue persists, consult the manufacturer’s troubleshooting guide or contact their customer support for assistance.

Remember, when troubleshooting any issues with your Panther Press Heat Press, always refer to the manufacturer’s instructions and follow proper protocols. Avoid attempting any repairs or modifications without professional guidance to prevent further damage to the machine.

If you are unable to resolve the issue on your own, contacting the manufacturer’s customer support team will provide you with expert guidance and assistance.

Safety Precautions and Recommendations

When cleaning your Panther Press Heat Press, safety should always be your top priority. Follow these essential precautions and best practices to ensure a safe and effective cleaning process.

Disconnect and Cool Down

Before starting the cleaning process, make sure your Panther Press Heat Press is fully disconnected from the power source. This minimizes the risk of electric shock or accidental activation of the machine. Additionally, allow the heat press to cool down completely to avoid burns or injuries.

Protective Gloves

When handling cleaning solutions and materials, it is advisable to wear protective gloves. This prevents direct contact with potentially harmful substances and minimizes the risk of skin irritation or allergic reactions.

Follow Manufacturer’s Instructions

Always adhere to the manufacturer’s instructions for cleaning solutions and materials. Different heat press models may require specific cleaning products or techniques. By following the recommended guidelines, you can ensure the best cleaning results and avoid any damage to the machine.

Consult the User Manual or Manufacturer

If you have any doubts or difficulties during the cleaning process, consult the user manual or contact the manufacturer for guidance. They can provide valuable insights and troubleshooting assistance to help you clean your Panther Press Heat Press effectively and safely.

By implementing these safety precautions and recommendations, you can confidently clean your Panther Press Heat Press, maintaining its optimal performance and durability without compromising your well-being.

Maintenance Schedule and Tips for Longevity

To maximize the lifespan of your Panther Press Heat Press, proper maintenance is key. By following a regular maintenance schedule and implementing a few essential tips, you can ensure the optimal performance and longevity of your heat press.

Cleaning

Regular cleaning is vital to keep your Panther Press Heat Press in top condition. Set a reminder to clean the machine after each use or at least once every two weeks, depending on your usage frequency. This helps prevent debris and residue buildup that can affect the heat transfer process and lead to lower quality prints.

When cleaning, focus on the platen, base, heating element, and exterior surfaces. Wipe the platen with a lint-free cloth or sponge dampened with a heat-resistant cleaning solution to remove any adhesive residue or ink buildup. Use a heat-resistant cleaning solution to clean the base and exterior surfaces, paying attention to button areas and control panels.

Don’t forget to lubricate the moving parts of your Panther Press Heat Press. Apply a small amount of silicone lubricant to hinges, springs, and other components as recommended by the manufacturer. This helps ensure smooth operation and prevents friction that can cause wear and tear.

Inspection and Maintenance

Regularly inspect your Panther Press Heat Press for any loose screws or components. Periodically tighten them to ensure everything is secure and in proper working order. Additionally, examine the electrical cords and plugs for any signs of damage. If you notice any frayed cords or bent plugs, replace them immediately to avoid potential electrical hazards.

Consider covering your heat press with a heat press cover when not in use. This provides an extra layer of protection against dust and other contaminants. By taking these maintenance measures, you can prolong the lifespan of your Panther Press Heat Press and save money in the long run.

Maintenance Schedule and Tips for Longevity

To summarize the maintenance schedule and tips for prolonging the lifespan of your Panther Press Heat Press:

- Clean the machine after each use or at least once every two weeks

- Wipe the platen, base, heating element, and exterior surfaces with a heat-resistant cleaning solution

- Lubricate the hinges, springs, and other moving parts with silicone lubricant

- Inspect and tighten any loose screws or components

- Regularly check the electrical cords and plugs for damage and replace if necessary

- Consider using a heat press cover when the machine is not in use

By following these maintenance tips, you can ensure the longevity and optimal performance of your Panther Press Heat Press, making it a reliable tool for all your heat transfer needs.

Conclusion

In conclusion, maintaining the cleanliness and functionality of your Panther Press Heat Press is crucial for optimal performance and longevity. By following the expert tips and best practices outlined in this guide, you can ensure that your heat press remains in top condition.

Regularly cleaning the platen, base, heating element, and exterior surfaces helps remove debris, maintain optimal heat transfer, and prevent contamination of transfers and substrates. Additionally, lubricating the moving parts of the heat press and adhering to a maintenance schedule will further prolong its lifespan.

It is important to prioritize safety during the cleaning process and follow the manufacturer’s instructions to avoid any mishaps. If you encounter any issues or need guidance, always consult the user manual or contact the manufacturer’s customer support for assistance.

By implementing these cleaning and maintenance practices, you can ensure the longevity and reliable performance of your Panther Press Heat Press, enabling you to create high-quality heat transfers consistently.

FAQ

Why is it important to clean my Panther Press Heat Press regularly?

Regular cleaning helps remove debris, adhesive residues, and ink buildup that can affect the heat transfer process and result in lower quality prints. It also prevents the transfer of dirt and contaminants onto garments or other substrates, ensuring a professional finish. Additionally, maintenance and cleaning prolong the lifespan of your Panther Press Heat Press.

What supplies and materials do I need to clean my Panther Press Heat Press?

You will need a lint-free cloth or sponge, heat-resistant cleaning solution or spray, silicone lubricant or heat press cover, and a soft brush or cotton swabs for hard-to-reach areas. It is important to use cleaning solutions and materials specifically designed for heat presses to avoid damaging the machine.

How do I clean the platen of my Panther Press Heat Press?

Disconnect the heat press from the power source and allow it to cool down completely. Then, use a lint-free cloth or sponge dampened with a heat-resistant cleaning solution to wipe the platen and remove any adhesive residue or ink buildup. For stubborn stains, gently scrub the platen with a soft brush or cotton swab. After cleaning, wipe the platen with a clean, dry cloth to remove any excess moisture.

How do I clean the base and exterior surfaces of my Panther Press Heat Press?

Unplug the machine and allow it to cool down completely. Use a lint-free cloth or sponge dampened with a heat-resistant cleaning solution to wipe the base and exterior surfaces, removing any dust, dirt, or debris. Pay special attention to button areas, control panels, and any other crevices or hard-to-reach areas. After cleaning, wipe the surfaces with a clean, dry cloth to remove any excess moisture.

How do I clean the heating element of my Panther Press Heat Press?

Before cleaning, ensure the heat press is disconnected from the power source and fully cooled. Use a soft brush or cotton swab to gently remove any debris or residue from the heating element. Avoid using harsh or abrasive materials that can damage the element. After cleaning, wipe the heating element with a clean, dry cloth to remove any remaining debris.

How do I lubricate the moving parts of my Panther Press Heat Press?

Apply a small amount of silicone lubricant to the hinges, springs, and other moving parts as recommended by the manufacturer. This helps ensure smooth operation and prevents friction that can lead to wear and tear. It is also advisable to cover the heat press with a heat press cover when not in use to protect it from dust and other contaminants.

What should I do if I encounter issues with my Panther Press Heat Press?

Refer to the manufacturer’s troubleshooting guide or contact their customer support for assistance. It is important to follow proper troubleshooting protocols and avoid attempting any repairs or modifications without professional guidance.

What safety precautions should I take when cleaning my Panther Press Heat Press?

Ensure the machine is fully cooled and disconnected from the power source before starting the cleaning process. Wear protective gloves to avoid direct contact with cleaning solutions. Follow the manufacturer’s instructions regarding the use of cleaning solutions and materials. If you encounter difficulties or have concerns, consult the user manual or contact the manufacturer for guidance.

What maintenance schedule should I follow for my Panther Press Heat Press?

Set a reminder to clean the machine after each use or at least once every two weeks, depending on usage frequency. Lubricate the moving parts and cover the heat press when not in use. Periodically check and tighten any loose screws or components. Regularly inspect the electrical cords and plugs for any signs of damage and replace them if necessary.

Conclusion

Proper cleaning and maintenance are essential for keeping your Panther Press Heat Press in top condition. Regularly cleaning the platen, base, heating element, and exterior surfaces helps remove debris, maintain optimal heat transfer, and prevent contamination of transfers and substrates. Additionally, lubricating moving parts and following a maintenance schedule prolong the lifespan of your heat press. Remember to prioritize safety during the cleaning process and consult the manufacturer’s instructions if you encounter any issues. By following the expert tips and best practices outlined in this guide, you can ensure the longevity and reliable performance of your Panther Press Heat Press.