Keeping your heat press clean is crucial for maintaining its performance and ensuring the quality of your heat-pressed creations. In this article, I will provide you with effective tips and best practices for cleaning a combo heat press machine. These tips will help you remove sticky marks, adhesive residue, dirt, vinyl residue, and ink smudges from your heat press, and keep it in excellent working condition. By following these cleaning instructions, you can avoid downtime, improve work efficiency, and extend the lifespan of your heat press machine.

Key Takeaways:

- Regular cleaning is essential for maintaining the performance of your combo heat press machine.

- Use mild soap and warm water, mineral spirits, or other suitable cleaning solutions for effective cleaning.

- Follow proper cleaning procedures to remove dirt, ink, and residue from your heat press.

- Be gentle when cleaning teflon-coated heat presses to avoid damaging the coating.

- Always clean your heat press at low temperatures or when it is turned off and unplugged for safety.

What to Clean Your Heat Press With?

When it comes to cleaning your heat press machine, it’s important to use the right cleaning solution to effectively remove dirt, ink, and residue. Here are some options you can consider:

- Mild Soap and Warm Water: This is the most common and gentle method for cleaning a heat press. Mix mild soap with warm water to create a solution that effectively removes dirt and ink from the platens.

- Mineral Spirits or White Spirits: If you need a more aggressive cleaner, try using mineral spirits or white spirits. These organic solvents are commonly used to dissolve oil-based materials like paint, ink, adhesive residue, grime, and dirt.

- Oven Cleaner: For tough stains or residue, an oven cleaner can be effective in removing them. Make sure to follow the instructions on the cleaner and take necessary precautions.

- Degreaser: A degreaser is another option for cleaning your heat press machine. It helps remove grease and grime from the platens, leaving them clean and ready for use.

- EZ Off Iron Cleaner: This specialized cleaner is designed specifically for removing adhesive residue and grime from heat press machines. It’s easy to use and leaves your machine looking clean and pristine.

Remember to choose a cleaning solution that is suitable for the specific type of dirt or residue you are trying to remove. Always follow the manufacturer’s instructions and take necessary safety precautions when using cleaning solvents.

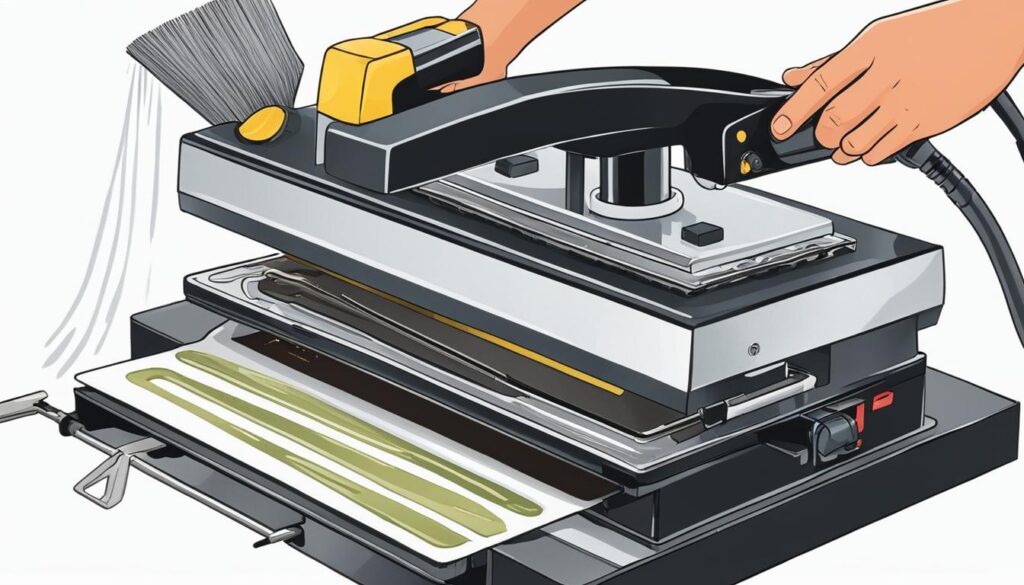

Steps to Clean Your Heat Press Using Mineral Spirits

Cleaning your heat press with mineral spirits is a simple and effective method to remove dirt, ink, and residue. Follow these steps to ensure a thorough cleaning:

- Dampen a clean rag with mineral spirits. Make sure the rag is not soaking wet, but damp enough to facilitate the cleaning process.

- Rub the dirty area of the heat press in a circular motion with the dampened rag. This motion helps to break down the dirt and ink.

- Allow the mineral spirits to soak in for about a minute, giving it time to penetrate and dissolve the dirt and ink.

- Using the rag, wipe away the loosened dirt and ink from the surface of the heat press. Repeat this process until the entire surface is clean.

- For a final touch, you can mix a small amount of liquid detergent with water and use it to wipe down both the upper and bottom platens. Start with the upper platen and then move to the bottom platen to remove any drippings from the upper platen.

By following these steps, you can effectively clean your heat press and ensure its optimal performance. Remember to always use mineral spirits in a well-ventilated area and follow proper safety precautions.

Why use mineral spirits?

Mineral spirits are organic solvents commonly used to dissolve oil-based materials like ink, paint, and adhesive residue. They are effective in breaking down and removing stubborn dirt and ink from the surface of a heat press.

Tips for a thorough cleaning

- Inspect your heat press before cleaning and identify any areas that require special attention.

- Apply gentle pressure when rubbing the rag on the heat press to avoid causing any damage.

- Repeat the cleaning process as necessary to ensure all dirt and ink are completely removed.

- Always clean your heat press when it is cool or turned off to prevent any accidents.

- Follow the manufacturer’s guidelines for cleaning and maintenance to avoid voiding any warranties.

| Benefits of Cleaning with Mineral Spirits | Things to Avoid |

|---|---|

|

|

Cleaning Teflon Coated Heat Presses

When it comes to cleaning a teflon coated heat press, gentle care is essential to protect the coating and avoid damage. It’s important to avoid scrubbing or scraping the teflon surface with any abrasive materials, as this can wear down the coating and compromise its effectiveness.

To clean a teflon coated heat press, you can follow the same steps mentioned earlier, using mineral spirits or a suitable cleaning solution. Apply the solution to a clean rag and gently wipe the surface of the heat press, focusing on any areas with dirt or residue. The mild cleaning solution should effectively remove any marks or stains without harming the teflon coating.

Note: Never use abrasive cleaning tools or harsh chemicals on a teflon coated heat press, as they can cause permanent damage. Always opt for gentle cleaning methods and appropriate cleaning solutions.

If your heat press does not have a teflon coating, you may consider applying a teflon spray to the top platen. This additional coating can provide an extra layer of protection and make it easier to remove any dirt or residue that may accumulate during heat pressing. Follow the manufacturer’s instructions for applying the teflon spray to ensure the best results.

Remember, maintaining the teflon coating on your heat press is crucial for optimal performance and longevity. By cleaning it properly and avoiding abrasive materials, you can ensure that your heat press remains in excellent condition for years to come.

Cleaning Your Heat Press While Turned On or Off

When it comes to cleaning your heat press, there are a few important things to consider, such as whether to clean it while it’s turned on or off. Generally, it is recommended to clean your heat press at low temperatures or when it is turned off and unplugged. This is especially crucial if you plan on using flammable solvents to clean your machine.

Using flammable solvents such as acetone can release toxic fumes when heated, posing a safety risk. To ensure your well-being, it is essential to read the label of the cleaning product and follow the manufacturer’s instructions for safety precautions. Additionally, it’s advisable to wear heat-proof gloves to protect yourself during the cleaning process.

Cleaning your heat press while it’s turned off not only minimizes the risk of accidents, but it can also prevent any disruptions in workflow. By setting aside dedicated time for cleaning and maintenance, you can maintain the longevity and performance of your heat press machine.

Safety Precautions for Cleaning a Heat Press

Here are some essential safety precautions to keep in mind when cleaning your heat press:

- Always turn off and unplug your heat press before cleaning.

- Ensure proper ventilation in the cleaning area to avoid inhaling any fumes or chemicals.

- Wear heat-proof gloves to protect your hands from hot surfaces and any cleaning chemicals.

- Read the label of the cleaning product and follow the manufacturer’s instructions for safe usage.

- Avoid using flammable solvents when your heat press is turned on, as this can lead to potential fire hazards.

By following these safety precautions, you can efficiently clean your heat press without compromising your well-being or the integrity of the machine.

| Cleaning method | Recommended for | Safety precautions |

|---|---|---|

| Mild soap and warm water | Removing dirt and ink from platens | Wear gloves, avoid excessive water on electrical components |

| Mineral spirits or white spirits | Removing adhesive residue, grime, and ink | Use in a well-ventilated area, wear gloves and eye protection |

| Oven cleaner | Tackling stubborn residue | Avoid direct contact with skin, wear gloves and eye protection, use in a well-ventilated area |

| Degreaser | Removing grease and oil-based stains | Use in a well-ventilated area, wear gloves and eye protection |

| EZ Off iron cleaner | Cleaning iron-on vinyl residue | Follow instructions on the packaging, avoid direct contact with skin |

Frequency of Cleaning Your Heat Press

Regular cleaning is essential to ensure the optimal performance and longevity of your heat press. By following a consistent cleaning schedule, you can prevent the buildup of dirt, ink, and other residues, and maintain the efficiency of your machine.

For most heat press owners, it is recommended to check and clean the heat press at least once a week. This regular maintenance routine usually takes around 15-20 minutes, making it a quick and manageable task. By dedicating a small amount of time each week to clean your heat press, you can avoid any potential issues that may arise from neglecting maintenance.

However, if you don’t use your heat press frequently, cleaning it once a month should be sufficient. This allows you to remove any accumulated dirt or residue that may hinder the performance of your machine. By incorporating regular cleaning sessions into your heat press maintenance schedule, you can optimize its operational life and ensure consistent, high-quality heat-pressed prints.

To illustrate the recommended cleaning frequency, refer to the following table:

| Heat Press Usage | Cleaning Frequency |

|---|---|

| Frequent Use (several times a week) | Once a week |

| Occasional Use (once a week or less) | Once a month |

Remember, regular cleaning of your heat press not only helps maintain its optimal performance but also extends its lifespan. By following a consistent cleaning routine, you can ensure that your heat press is always ready to deliver professional and long-lasting heat-pressed creations.

Proper Storage of Your Heat Press

When it comes to maintaining your heat press, proper storage is just as important as regular cleaning. Storing your heat press correctly can help prolong its lifespan and ensure it remains in optimal condition. Here are some essential storage tips:

- Find a clean and protected area: Choose a storage space that is free from dust, dirt, and other contaminants. Keep your heat press away from areas with high humidity, as moisture can lead to rust or corrosion on the heating platen.

- Keep it cool and dry: Ideally, the storage space should be cool and dry to prevent condensation and moisture buildup. Consider using a dehumidifier if necessary to maintain a low humidity level.

- Cover your heat press: Protect your heat press from dust and other elements by using a cover or a clean cloth. This will help prevent dirt from accumulating on the machine, ensuring it stays in top condition.

- Lubricate moving parts: Check for any moving parts, such as levers and pivot joints, and ensure they are well lubricated. Using a rust-preventive lubricant can help keep these parts functioning smoothly and prevent rust formation.

By following these storage tips, you can safeguard your heat press from moisture, dust, and rust, and ensure its longevity and performance.

| Storage Tips | Description |

|---|---|

| Find a clean and protected area | Choose a storage space that is free from dust and other contaminants. Avoid storing in high humidity areas. |

| Keep it cool and dry | Store your heat press in a cool and dry environment to prevent moisture buildup. |

| Cover your heat press | Protect your heat press from dust and other elements by using a cover or a clean cloth. |

| Lubricate moving parts | Check and lubricate any moving parts to prevent rust and ensure smooth operation. |

Best Practices for Maintaining a Heat Press

Keeping your heat press clean and well-maintained is crucial for ensuring its longevity and optimal performance. By following these best practices, you can keep your heat press in top condition and produce high-quality heat-pressed prints.

1. Use a Teflon Sheet or Parchment Paper

When heat pressing garments, it’s important to prevent direct contact between the heat plate and the fabric. To achieve this, use a teflon sheet or parchment paper as a protective barrier. This not only helps prevent scorching or discoloration of the fabric but also keeps the heat plate clean, reducing the need for frequent cleaning.

2. Double-Check Transfers Before Pressing

Before pressing a design onto your garment, take a moment to carefully inspect the transfer. Ensure that it is properly aligned and free from any defects or imperfections. This step helps avoid wasted materials and ensures that you achieve the desired result.

3. Work in a Clean Area

Creating heat-pressed prints in a clean and clutter-free environment is essential for maintaining the quality of your prints. Avoid working in dusty or dirty areas that can transfer impurities onto the garment. Regularly clean your work area, removing any debris or residue that may affect the heat press process.

4. Protect the Bottom Platen

The bottom platen of your heat press can come into contact with various materials, including adhesive residue and stray ink. To protect the bottom platen and keep it clean, consider using a pad protector or teflon sheet. These protective measures not only prevent damage to the platen but also make it easier to clean and maintain.

5. Perform Test Presses

Before proceeding with a full production run, it’s always advisable to perform test presses. Use clean rags or sacrificial pieces of fabric to test the transfer process. By doing so, you can ensure that there are no impurities on the heat platen that could affect the quality of your prints.

| Best Practices | Benefits |

|---|---|

| Using a Teflon Sheet or Parchment Paper | Prevents direct contact between heat plate and fabric Reduces the need for frequent cleaning |

| Double-Checking Transfers Before Pressing | Avoids wasted materials Ensures desired print quality |

| Working in a Clean Area | Maintains print quality by preventing impurities Creates a professional and organized work environment |

| Protecting the Bottom Platen | Prevents damage to the platen Simplifies cleaning and maintenance |

| Performing Test Presses | Ensures absence of impurities on the heat platen Maintains consistency and quality of prints |

By following these best practices, you can ensure that your heat press machine remains clean, efficient, and productive. Incorporating these practices into your routine maintenance will help you achieve consistent and high-quality heat-pressed prints.

Conclusion

Maintaining a clean heat press is essential for optimizing its performance and extending its lifespan. By following the heat press cleaning tips and best practices mentioned in this article, you can effectively remove dirt, ink, and residue from your machine, ensuring the quality of your heat-pressed creations.

Regularly cleaning your heat press is key to preventing transfer failures and improving work efficiency. Remember to clean your heat press at least once a week, or once a month if you don’t use it frequently. Additionally, store your heat press in a clean and protected area to avoid moisture damage and rust formation.

As you clean your heat press, make sure to use suitable cleaning solutions and follow safety precautions. Choose the right cleaning solution based on the type of dirt or residue you want to remove. When using flammable solvents, clean your heat press at low temperatures or when it is turned off and unplugged to ensure your safety.

By maintaining a clean heat press and following these cleaning tips, you can optimize the performance of your machine and achieve high-quality heat-pressed prints consistently.

FAQ

What are some effective tips for cleaning a combo heat press machine?

Cleaning your combo heat press machine is essential for its performance and longevity. Some effective tips include using mild soap and warm water, mineral spirits or white spirits, oven cleaner, degreaser, or EZ Off iron cleaner. Choose a cleaning solution based on the type of dirt or residue you need to remove.

How do I clean my heat press using mineral spirits?

To clean your heat press using mineral spirits, dampen a clean rag with the solvent and rub the dirty area in a circular motion. Let it soak for a minute, then clean off the dirt or ink with the rag. Repeat until the entire surface is clean. Finish by wiping both platens with a mixture of liquid detergent and water.

How should I clean a teflon coated heat press?

When cleaning a teflon coated heat press, it’s important to be gentle to avoid damaging the coating. Use mineral spirits or a suitable cleaning solution and follow the same cleaning process. If your heat press doesn’t have a teflon coating, consider applying a teflon spray to the top platen for easier cleaning.

Should I clean my heat press while it is turned on or off?

It is generally recommended to clean your heat press at low temperatures or when it is turned off and unplugged. This is especially important when using flammable solvents like acetone. Always read the label and follow the manufacturer’s safety instructions.

How frequently should I clean my heat press?

It is a good practice to check and clean your heat press at least once a week. If you don’t use it frequently, cleaning once a month should suffice. Regular cleaning prevents the buildup of dirt, ink, and other residues, maintaining optimal performance.

What is the best way to store my heat press?

Store your heat press in a clean and protected area, preferably cool and dry, to prevent rust or corrosion. Cover it to protect it from dust. Lubricate any moving parts and ensure they are in good condition.

Are there any best practices for maintaining a heat press?

Yes, some best practices include using a teflon sheet or parchment paper, double-checking transfers before pressing, working in a clean area, protecting the bottom platen, and performing test presses. These practices ensure high-quality heat-pressed prints and prevent transfer failures.

How important is it to maintain and clean my heat press?

Proper maintenance and cleaning of your combo heat press machine are vital for optimal performance and longevity. By following the cleaning tips and best practices, you can effectively remove dirt, ink, and residues, prevent transfer failures, and extend the lifespan of your machine.